Dim sum wrapping machine

Semi-Automatic Shumai Machine

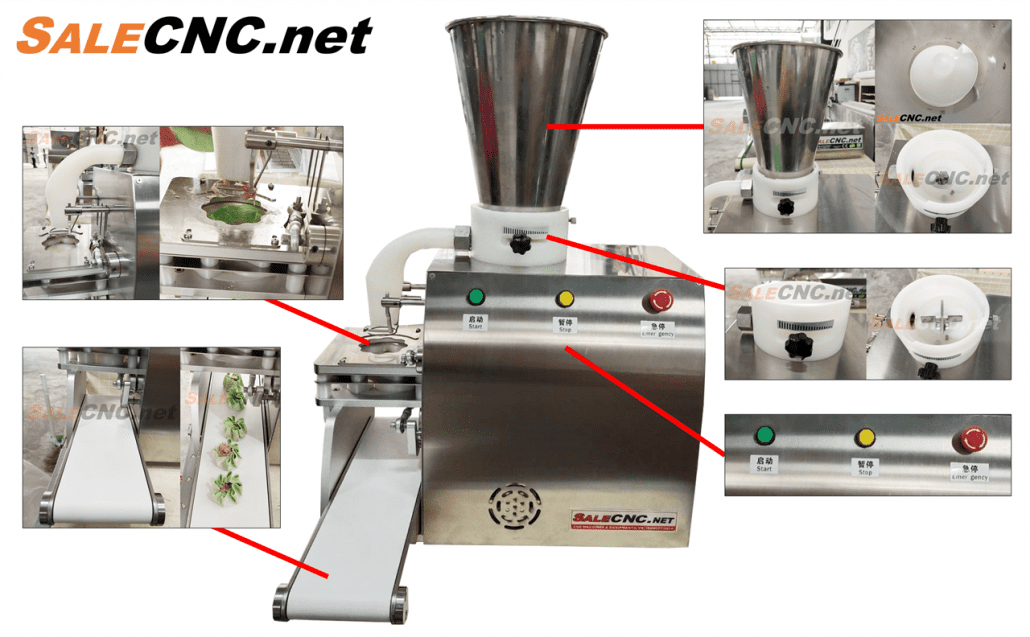

Dim sum maker Tabletop 1-slot Shumai Wrapping Machine, Dim Sum Semi-Automatic Shumai Machine (Production quantity depends on the speed of laying the dough sheet)

Dim sum wrapping machine, investment of tens of thousands!! You can create your shop brand right away.

Dim sum making machine, Dim sum wrapping machine, fast production, low cost, no complicated steps, ready to sell!!

Semi-Automatic Shumai Machine Working Video

Specifications of the Dim Sum Maker

✅ Steamed dumplings A famous menu that everyone knows, which from the beginning this menu appeared in Mongolia. There were merchants selling it in tea shops on the Silk Road until it was called Shao-Mai, which means side dish or appetizer eaten with tea. Later, shao mai was brought to Beijing during the Ming-Qing Dynasties. China then called this menu dumplings, which is how we know it today.

✅ The word "shumai" comes from Cantonese and means cooking small bites. It also has different names depending on the region, such as shao mai, tiansin, xiao mi, shao mai, dim sum, etc.

✅ In addition, this dumpling making machine is also suitable for producing various types of food that are packaged similar to dumplings, dim sum, Chinese food.

✅ Can be applied in food processing plants, frozen food that require high production capacity, helps increase productivity, save time, and also reduce labor.

✅ The steps are not complicated. One person can control the machine.

In addition, this dumpling making machine is also suitable for producing various types of food that are packaged similar to dumplings, dim sum, and Chinese food.

Each piece of dumpling is of standard quality, and the manufacturer can control production costs.

Machine Components (Components of the Dim Sum Wrapping Machine)

Overall components

1. Stuffing can – stuffing can

2. Fill volume adjustment handle – Adjust the filling level.

3. Rack – Empty

4. Emergency stop switch – Emergency stop switch

5. Pause – Pause button

6. Start key – Start button

7. Conveyor belt – Conveyor belt

8. Bottom filling base – Bottom filling base

9. Bend down filling pipe – Pipe for filling

10. Robot hand – Robot hand

11. Skin pressure ring – Dumpling sheet pressing ring

12. Leather stand – Dumpling stand

13. Front ront standboard – Front shock stand

Video of disassembly and assembly of a dim sum machine

Stuffing cavity

Propeller inside the filling chamber

Bottom fill base

Bottom fill base

Adjust the filling level

Tube for filling

Conveyor belt

The machine in the picture is Automatic Dumpling Maker Which can be used to produce food such as Dim sum, gyoza, boiled dumplings or steamed dumplings Fast and continuous, suitable for food factories, restaurants or SME entrepreneurs who want to increase production capacity by reducing the use of manpower.

Components of the machine:

-

Top Filling Tank - Add pork, chicken, shrimp or other fillings as desired.

-

Dough sheet compartment – Some models have an automatic dough pulling belt.

-

Molding and wrapping system – The machine will put the filling into the dough sheet and squeeze it to form the shape of a dumpling or a dumpling.

-

Conveyor belt – Take out the shaped dumplings and prepare to steam or fry them.

Highlights of the machine:

-

Save labor, work continuously

-

High production speed (tens to hundreds of balls per minute)

-

Easy to clean because it is stainless steel.

-

You can change the mold to make different kinds of dumplings or dumplings.

Examples of food produced:

-

Pork dumplings, shrimp dumplings

-

Japanese dumplings

-

Dumplings boiled in soup

-

Crispy fried dumplings

Machine Dimension (Dimension of Dim Sum Wrapping Machine)

Applied in food processing plants and frozen food factories that require high production capacity.

The steps are not complicated and one person can control the machine.

Front view of the dumpling making machine

Back view of the dumpling making machine

The machine requires a working area of 43 x 36.5 x 56 cm.

Features of the Dim Sum Maker

✅ Compact size, takes up little working space, helping you save a lot of space.

✅ Production quantity depends on the speed of laying the dough sheets.

✅ It has a safe controller system, easy to use, and the steps are not complicated. One person can control the machine.

✅ Customizable and designed to fit the user's needs

✅ Adjustable speed of the turntable helps increase productivity, save time, and also reduce labor.

✅ Adjustable speed of the steamer blade helps to mix the ingredients perfectly.

✅ Adjustable weight of dim sum, control the amount of filling in dim sum

✅ The structure of the dumpling making machine is made of 304 stainless steel, a good quality material (Food Grade), ensuring hygiene.

It helps increase productivity, saves time, and also reduces labor.

Working process of the dumpling wrapping machine (semi-automatic)

The Dim Sum Wrapping Machine has a simple operation principle with only 4 steps as follows:

1. The operator places the dumpling sheets.

2. The operator presses the power button to start the machine.

3. Machine for stuffing the dumpling filling into the dough, folding and pleating.

4. The wrapped dumplings are placed on the conveyor belt.

The steps are not complicated and one person can control the machine.

The production quantity depends on the speed of laying the dough sheets.

Dim sum wrapped in a dim sum maker

Dim sum wrapped in a dim sum maker

Advantages of usingDim sum maker

✅ Reduce the time spent wrapping dumplings. You can work continuously, which is faster than manual labor, which can only do 1 piece at a time.

✅ Even if you don't have any prior knowledge of wrapping dumplings, you can still use the machine. The machine is fully automatic and easy to use.

✅ Low investment but high yield. Manufacturers invest only once and can use the machine for a long time. It is worth the investment when compared to the cost of hiring labor.

✅ Easy maintenance, long service life, and disassembly for cleaning.

✅ Clean and hygienic. The operator has the least chance of touching food, thus reducing the chance of food contamination.

✅ Maintain product quality. The dumpling filling is mixed until it is well blended. Using a dumpling wrapper will make the product fresh, delicious, and maintain consistent quality in every piece.

Automatic Dumpling and Wonton Maker | High-Speed Food Processing Machine

Boost your food production with our Automatic Dumpling and Wonton Making Machine, ideal for factories, restaurants, and food startups. This high-efficiency machine is designed to produce a variety of dumplings such as Siu Mai (Shumai), Gyoza, Wontons, and Steamed Dumplings with consistent quality and speed.

✅ Key Features:

-

Fast Production: Up to hundreds of dumplings per hour — perfect for high-demand businesses.

-

Multi-Function: Makes dumplings, wontons, gyoza, and more with customizable molds.

-

Stainless Steel Build: Hygienic, durable, and easy to clean.

-

User-Friendly: Simple control panel with automatic filling, shaping, and output.

-

Adjustable Size: Easily change the size or shape of dumplings based on your recipe.

🍽 Suitable for:

-

Frozen food manufacturers

-

Dim sum shops

-

Cloud kitchens

-

Food delivery brands

-

Restaurants and catering services

📦 Applications:

Make a variety of Asian dumplings such as:

-

Pork and shrimp shumai

-

Chicken wontons

-

Vegetable gyoza

-

Thai-style steamed dumplings

Add Line: @123wotsb Fern (sales engineer)

Add Line: @123wotsb Fern (sales engineer)  Add Line: @sales Chompoo (sales engineer)

Add Line: @sales Chompoo (sales engineer)

Reviews

There are no reviews yet.