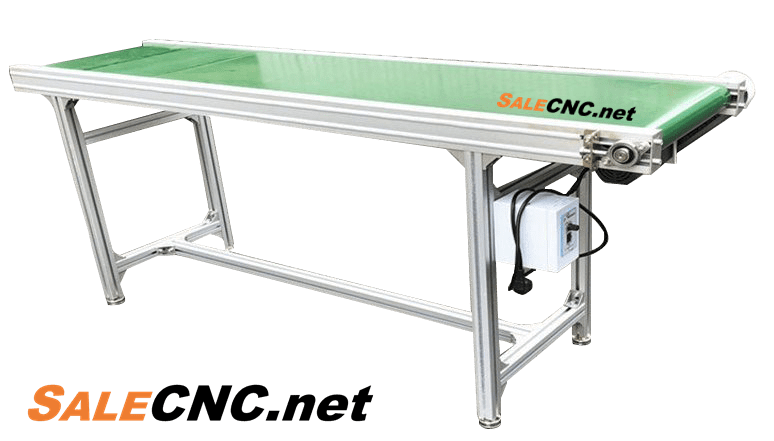

Conveyor Belt PVC

Conveyor belt, PVC conveyor belt

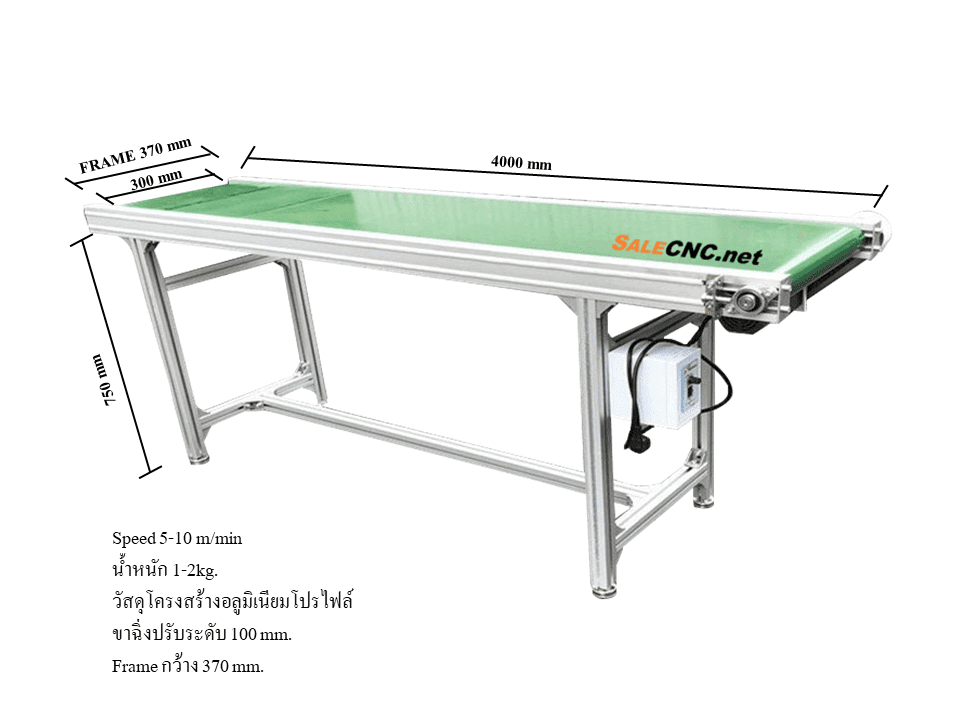

Standard height (non-adjustable)

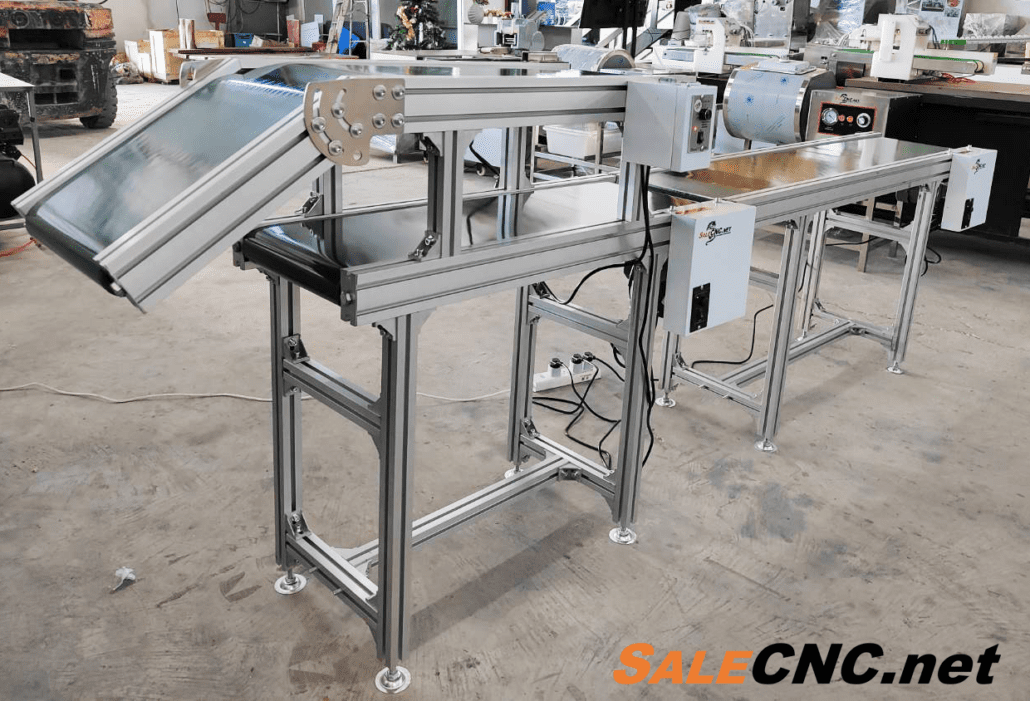

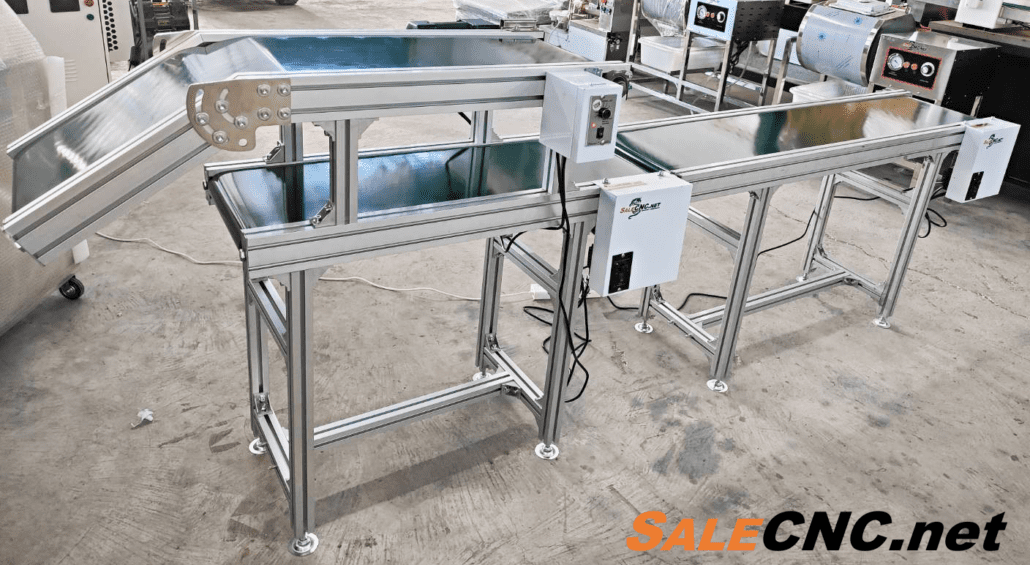

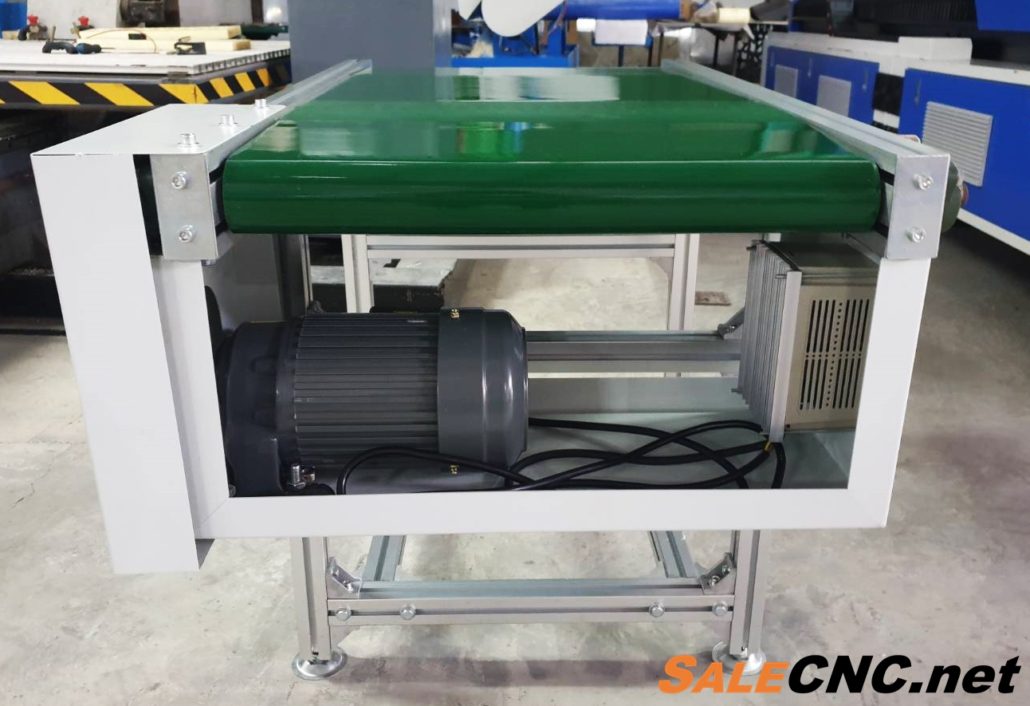

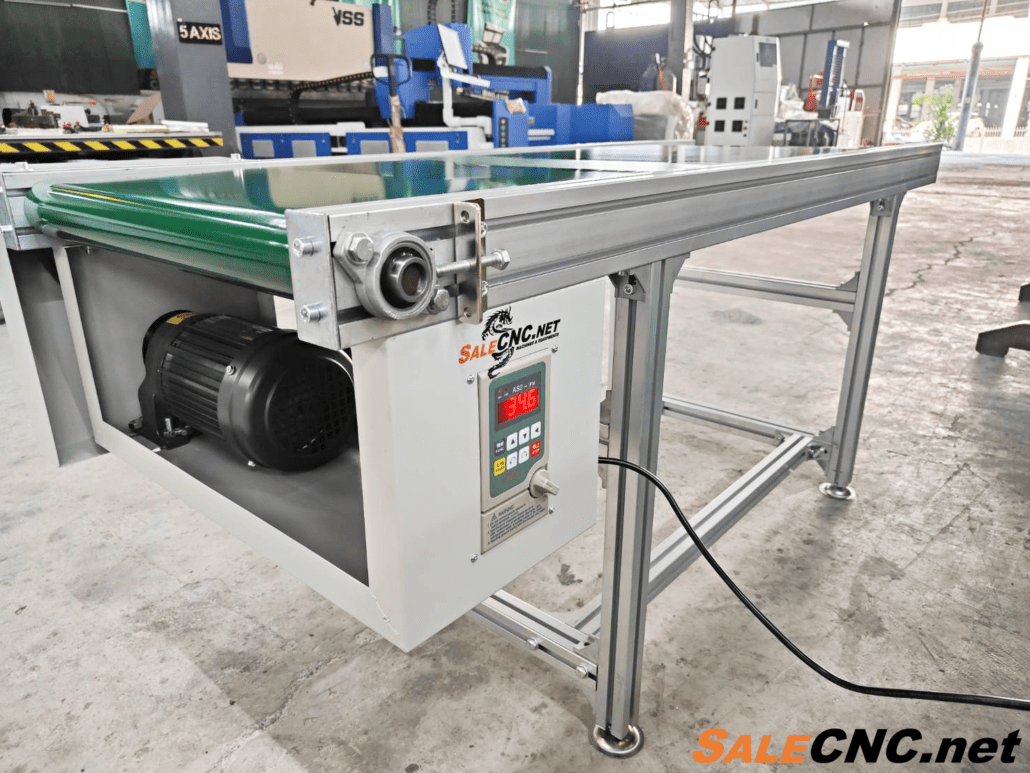

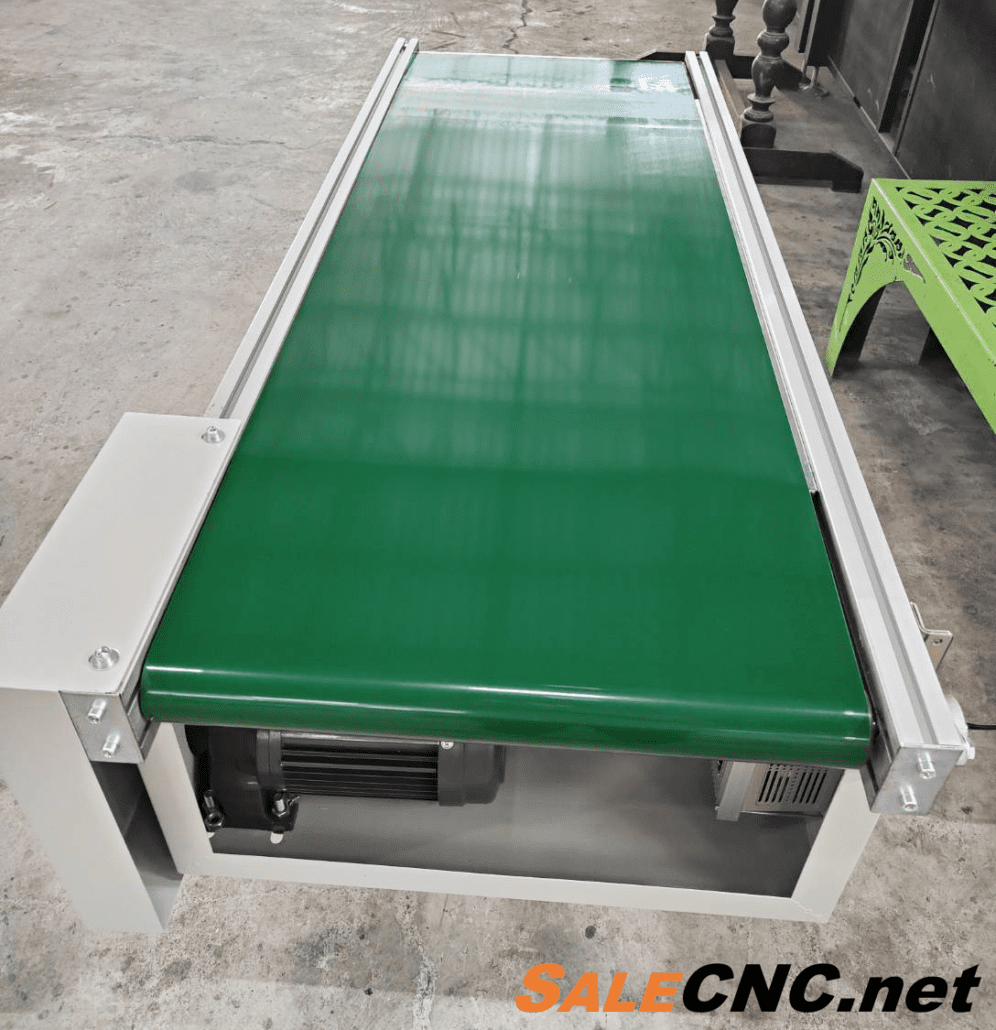

- It is a conveyor belt for moving things - a PVC type material handling machine.

- Uses an electric motor, flow speed can be adjusted.

- Easy to move materials or transport things. Easy to install and use.

- Standard height of the machine (Standard height) 75 cm. (non-adjustable)

- Product on conveyor about 30kg

Polyvinylchloride (PVC) / Polyvinyl chloride

- PVC has good resistance to high temperatures, tensile strength, and cut and puncture resistance.

- PVC has abrasion resistance.

- PVC is resistant to oil and has good odor resistance.

- PVC is durable and resistant to abrasion.

- Conveyor Belt PVC 300x1500x750 mm

- Conveyor Belt PVC 300x1000x750 mm

- Conveyor Belt PVC 300x1200x300 mm

- speed 8-13 m/min

- Weight 2-3 kg.

The whole set is 46,000.-

Inverter motor Motor speed ratio 30-40m/min. 7500 baht

- Conveyor Belt PVC 500x1000x750 mm

- Speed 40 m/min, adjustable cymbal legs 100 mm.

- Supports weight of 3 kg. on both belts.

- Price 32,000 baht

- Conveyor Belt PVC 500x1500x750 mm

- Speed 40 m/min, adjustable cymbal legs 100 mm.

- Supports weight of 3 kg. on both belts.

- Price 32,000.-

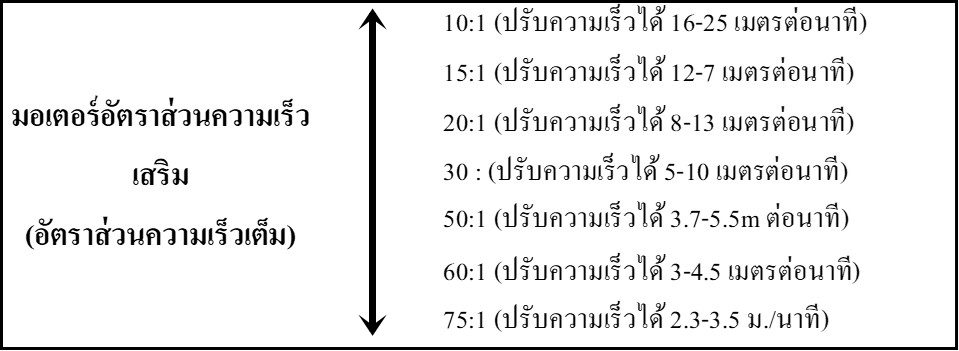

Conveyor Belt PVC Speed Specification

**England**

**Thai language**

size

| Width x Length | |||||||

|---|---|---|---|---|---|---|---|

| size | 1500 | 2000 | 2500 | 3000 | 3500 | 4000 | 4500 |

| 300 | 300×1500 mm | 300×2000 mm | 300×2500 mm | 300×3000 mm | 300×3500 mm | 300×4000 mm | 300×4500 mm |

| 500 | 500×1500 mm | 500×2000 mm | 500×2500 mm | 500×3000 mm | 500×3500 mm | 500×4000 mm | 500×4500 mm |

| 600 | 600×1500 mm | 600×2000 mm | 600×2500 mm | 600×3000 mm | 600×3500 mm | 600×4000 mm | 600×4500 mm |

- Product on conveyor about 30kg

**England**

- A conveyor belt is a mechanical device consisting of a continuous loop of material typically made of rubber, fabric, or metal, used for transporting objects from one location to another. Conveyor belts are commonly used in manufacturing, distribution centers, warehouses, airports, and many other industries for the efficient movement of goods, products, and materials.The basic components of a conveyor belt system include:Belt: The conveyor belt itself is the component that carries the load. It can be made from various materials depending on the application, such as rubber, PVC, nylon, or metal.Drive Mechanism: This is the mechanism that powers the movement of the conveyor belt. It may consist of an electric motor, hydraulic system, or other power source.Idlers or Rollers: Idlers or rollers are placed along the length of the conveyor belt to support and guide it. They help reduce friction and ensure smooth movement.Pulleys: Pulleys are used to change the direction of the belt or provide tension to keep the belt tight. They are typically located at the ends of the conveyor belt.

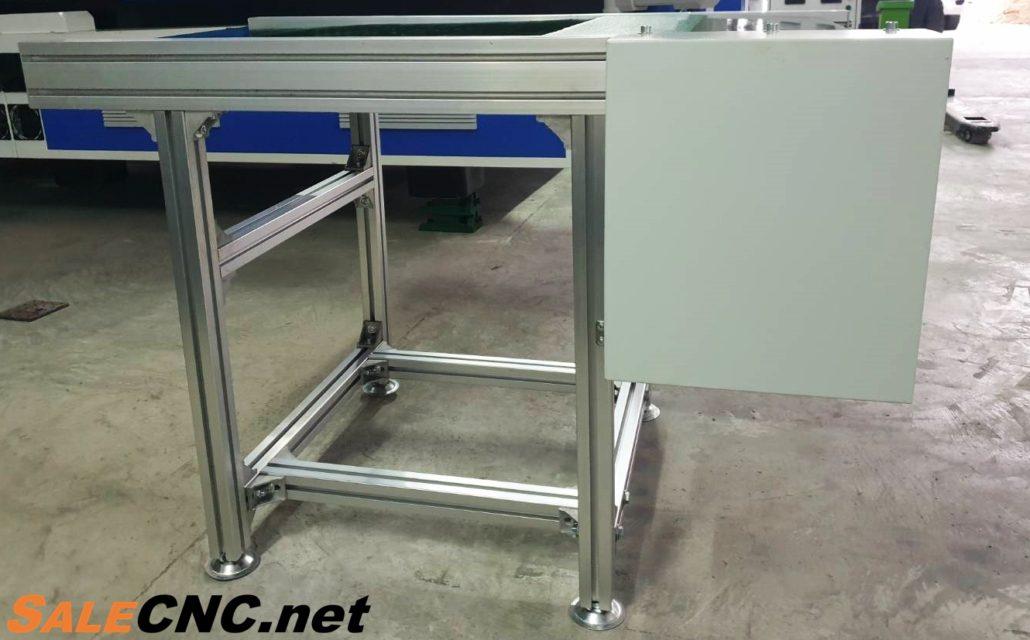

Support Structure: The support structure provides the framework for the conveyor belt system, including the frame, legs, and other structural components.

Conveyor belts can be configured in various ways depending on the specific needs of the application. They can be straight, curved, inclined, or declined, and may incorporate additional features such as side rails, cleats, or guides to control the movement of the transported items.

Conveyor belts offer several advantages, including efficient transportation, automation of material handling processes, increased productivity, and reduced manual labor. They come in a wide range of sizes and configurations to suit different industries and applications.

**Thai language**

- A conveyor belt is a mechanical device consisting of a continuous ring of material, typically made of rubber, fabric, or metal, used to transport objects from one place to another. Conveyor belts are commonly used in manufacturing, distribution centers, warehouses, airports, and many other industries to efficiently move goods, products, and materials. The basic components of a conveyor system include: Belt: The conveyor belt itself is the load-bearing component. It can be made of a variety of materials, depending on the application, such as rubber, PVC, nylon, or metal. Drive mechanism: This is the mechanism that drives the movement of the conveyor belt. It may consist of an electric motor, hydraulic system, or other power source. Rollers or rollers: Rollers or rollers are placed along the length of the conveyor belt to support and guide it. They reduce friction and allow for smooth movement. Pulleys: Pulleys are used to change the direction of the belt or to provide tension to keep the belt tight. They are usually located at the ends of the conveyor belt.

Support Structure: The support structure is the frame for the conveyor system, including the frame, legs and other structural components.

Conveyor belts can be configured in a number of ways, depending on the specific needs of the application. These can be straight, curved, inclined, or deflected, and may include additional features such as side rails, cleats, or guide rails to control the movement of the items being transported.

Conveyor belts offer many advantages, including efficient transportation, automated material handling processes, increased productivity, and reduced manual labor. They come in a variety of sizes and configurations to suit different industries and applications.

Reviews

There are no reviews yet.