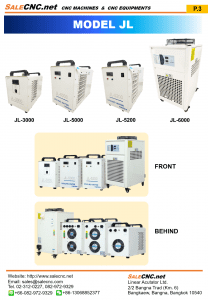

Chiller Water Cooling Chiller

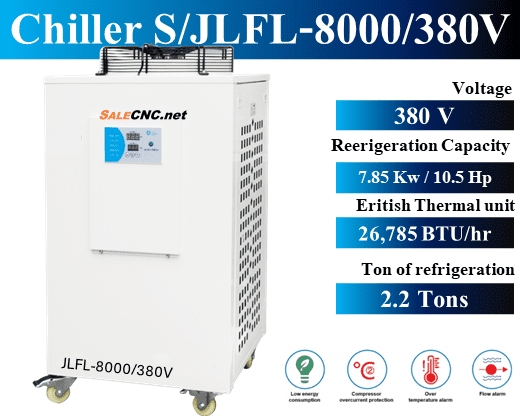

เครื่องทำความเย็น JLFL-8000 / 380V

Chiller Chiller Water Cooling

Cooling system, cooling system, chiller / industrial water chiller, water chiller for factory

Precise Temperature Control Industrial Cooling System

- Thailand is located in a tropical area. The weather is hot all year round. In the use of machinery, electronic equipment and other devices in industrial plants, when the temperature increases, the inside of the machine will overheat, resulting in equipment damage, inefficient operation and if the heat accumulates more and more, it may cause a fire. The heat in the machine is like the heat in a person's body. When our body temperature is higher than normal, we will get sick and will not be able to do things efficiently. Therefore, we take into account the maintenance of the machine and can solve the problem of high temperature machines by: Chiller Be a helper

- Thailand is located in the tropical zone. It is hot all year round. In machine operation Electronic device and other industrial equipment when there is an increase in temperature causing the inside of the machine to overheat resulting in malfunctioning equipment not working efficiently and find more and more heat equations there may be a fire. Machine heat Is like the heat of a person's body, when the body temperature increases beyond normal we will get sick and unable to do things at their full potential Therefore, we consider the maintenance of the machine. And can solve problems with high temperature machines with Chiller to help.

- Chiller It is a cooling machine, a water chiller, both large and small. Its main function is to produce coolness, reduce the temperature and dissipate heat by using water as the main factor in exchanging and transferring coolness from the chiller. Currently, chillers are used in industrial plants to cool machines, maintain machines to last longer and help maintain the efficiency of the machines.

- Chiller is a refrigeration. Water cooler There are both large and small. It is the main function of cold production reduce the temperature and cooling.

- Use water as the main medium for exchanging and dissipating heat from the cooling machine.

- Chillers are currently used in industrial plants to cool down machines, maintain them for a long time, and help maintain their efficiency.

- For example, closed-loop wells, hydraulic injection molding machines, and CNC machines.

- For example : Closed system pond, Hydraulic injection molding machine, CNC Engraving Cutting CO2, CNC Laser Engraving UV, CNC Router Milling, CNC Fiber Laser and other.

Chiller for sale, model JLFL-8000

Used for cooling CNC fiber laser machines. Easy to use, makes the CNC fiber laser machines not hot while working.

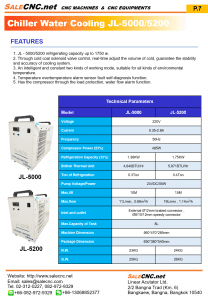

FEATURES

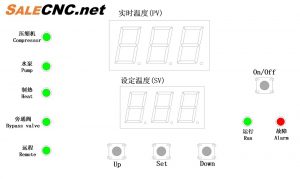

- Dual digital tube display, set temperature and real-time temperature at a glance.

- Full power refrigeration, micro refrigeration, heating control.

- With high precision temperature control, fluctuation can be controlled within 0.5℃.

- Sensor fault self-diagnosis function water flow alarm function.

- The main board adopts high integration chip with strong anti-interference ability.

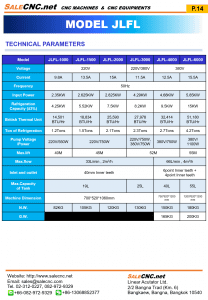

Machine Dimension

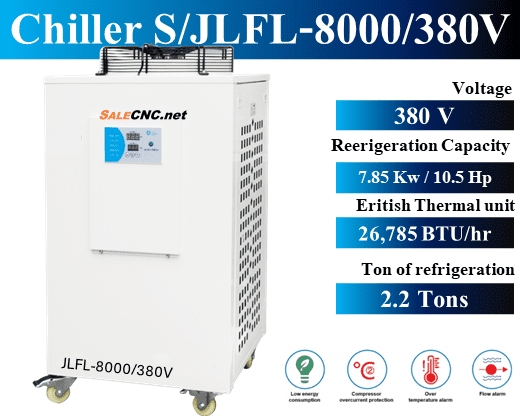

Alarm

Controller page

Top part

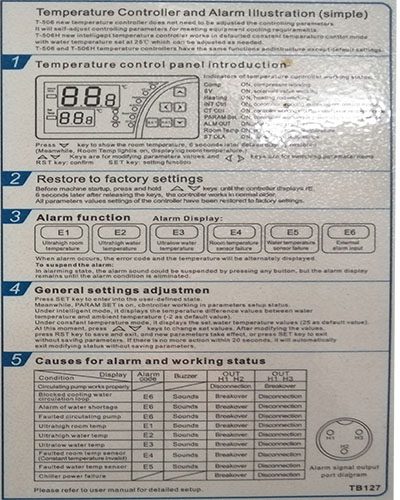

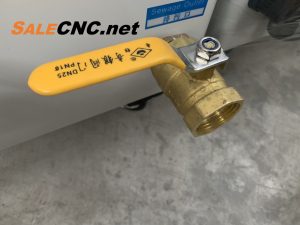

inlet and outlet

Displays the water level inside the machine

Drain hole

The device comes with the device

Side of the machine

Back of the machine

Additional function of the drain pipe, can choose to buy inside diameter 19 or 32 mm.

Drainage pipe inside diameter 32 mm

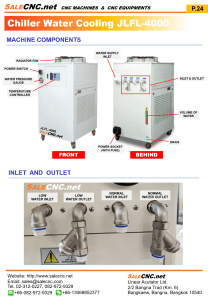

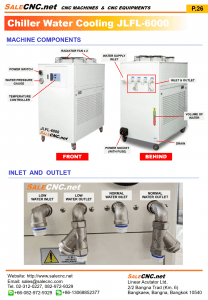

Machine Components

Inlet and Outlet

Download the JLFL Chiller User Manual Click here

How is BTU measured?

BTU, or British Thermal Unit, is a unit of measurement used to measure the amount of heat energy required to raise the temperature of one pound of water by 1 degree Fahrenheit at constant pressure. It is commonly used in the United States and other countries to measure heating and cooling capacity.

The BTU measurement process involves several steps:

- Define the system: Define the system that will measure BTUs. For example, it could be a heating system, a cooling system, or an appliance like a furnace or water heater.

2. Identify the substance: Identify the substance whose heat energy is to be measured. In many cases, this is water, but it can vary depending on the application.

3. Measure the temperature change: Measure the initial and final temperature of the substance. For example, if you are measuring the BTUs generated by burning fuel in a furnace, you will need to measure the water temperature before and after the heat exchange process.

Calculate Thermal Energy: Use the formula to calculate thermal energy in BTU:

Thermal energy (BTU)

–

Mass (pounds)

Specific heat (BTU/lb°F)

Temperature change (°F)

Heat energy (BTU) = mass (pounds) × specific heat (BTU/lb°F) × change in temperature (°F)

5. Here, “mass” means the mass of a substance in pounds, “specific heat” means the specific heat capacity of a substance in BTUs per pound per degree Fahrenheit (BTU/pound °F), and “change in temperature” means the change in temperature in degrees Fahrenheit.

6. Accounting for Efficiency: In some cases, it may be necessary to take into account the efficiency of the system or device being measured to determine the actual BTU output or input.

Overall, BTU measurement is a standard way to quantify heat energy required for a variety of applications, including HVAC (heating, ventilation, and air conditioning), cooking, and industrial processes.

BTU, or British Thermal Unit, is a unit of measurement used to quantify the amount of heat energy required to raise the temperature of one pound of water by one degree Fahrenheit at a constant pressure. It's commonly used in the United States and other countries for measuring heating and cooling capacities.

The process of measuring BTUs involves several steps:

- Define the System: Determine the system for which the BTU measurement is being made. For example, it could be a heating system, a cooling system, or an appliance like a stove or water heater.

2. Identify the Substance: Determine the substance for which the heat energy is being measured. In many cases, this is water, but it can vary depending on the application.

3. Measure Temperature Change: Measure the initial temperature and final temperature of the substance. For example, if measuring the BTUs generated by burning fuel in a furnace, you would measure the temperature of the water before and after the heat exchange process.

4. Calculate Heat Energy: Use the formula to calculate the heat energy in BTUs:

Heat energy (BTU)

=

mass (lb)

×

specific heat (BTU/lb°F)

×

temperature change (°F)

Heat energy (BTU)=mass (lb)×specific heat (BTU/lb°F)×temperature change (°F)

Here, “mass” refers to the mass of the substance in pounds, “specific heat” refers to the specific heat capacity of the substance in BTU per pound per degree Fahrenheit (BTU/lb°F), and “temperature change” refers to the change in temperature in degrees Fahrenheit.

5. Account for Efficiency: In some cases, the efficiency of the system or device being measured may need to be taken into account to determine the actual BTU output or input.

Overall, BTU measurement provides a standardized way to quantify heat energy, which is essential for various applications, including HVAC (heating, ventilation, and air conditioning), cooking, and industrial processes.

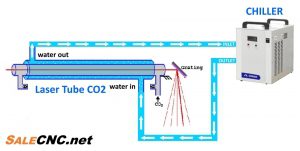

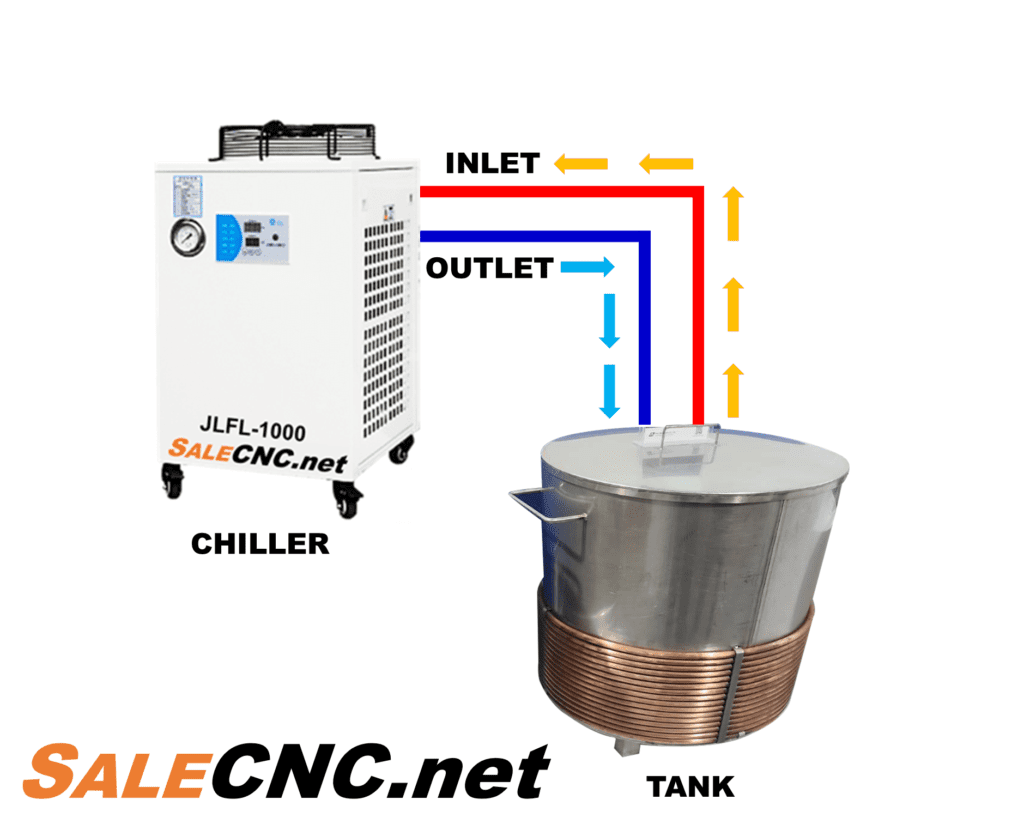

Working between CO2 Laser Tube and Chiller

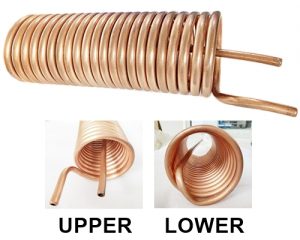

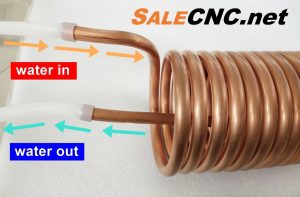

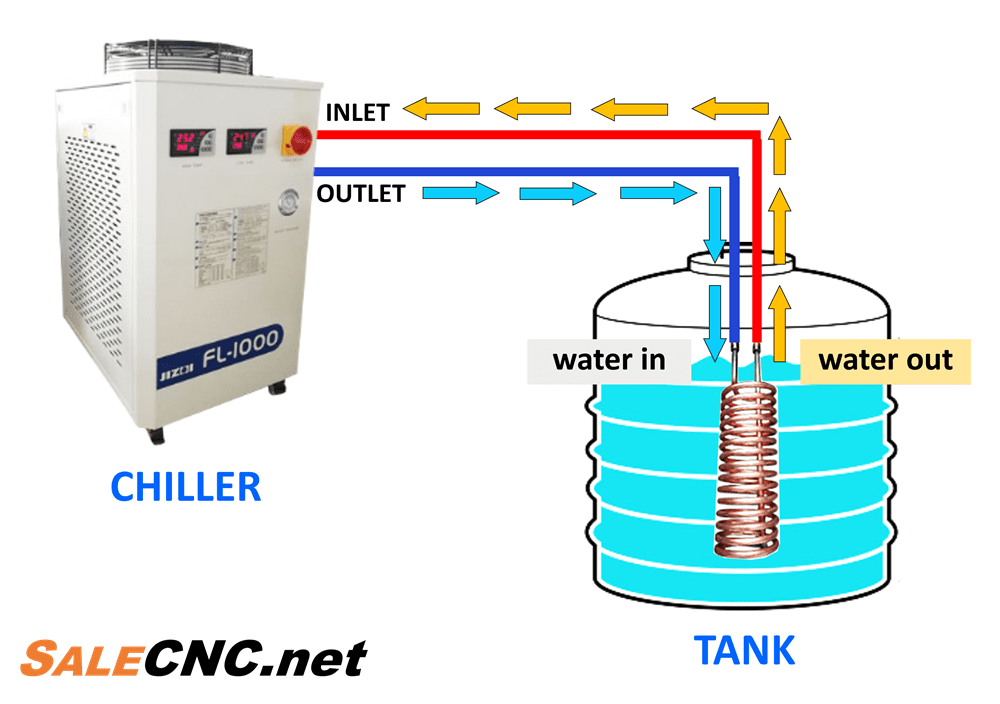

Additional options: Heat Exchanger

Heat Exchanger Connect to the Chiller and immerse in water to further reduce the water temperature.

The price is only 3,000 baht!!

Installation of Heat Exchanger with chiller

Heat Exchanger Accessories for chillers to further reduce water temperature | SALECNC.net

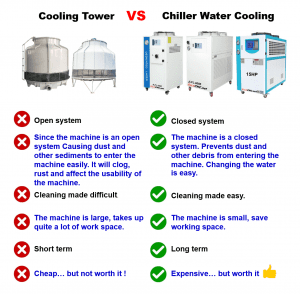

Chiller Water Cooling VS Cooling Tower

Cooling Tower Used in industry Hydraulic Injection Molding Machine Mostly because cooling towers have quite a few disadvantages. The machine is large, it is an open system that is difficult to maintain, dust and sediment are easily able to enter the machine, which negatively affects the operation and shortens the lifespan.

Therefore, the manufacturing industry tends to turn to use Chiller (Chiller Water Cooling) The machine is small, compact, saves working space, is a closed system, prevents dust and sediment well, and has a long service life.

| Cooling Tower | Chiller Water Cooling |

|---|---|

| ❌ Open system

❌ Open system operation |

✅ Closed system

✅ Closed-system operation |

| ❌ Since the machine is an open system Causing dust and other sediments to enter the machine easily. It will clog, rust and affect the usability of the machine.

❌ Since it works as an open system, dust, debris, etc. are very likely to enter the machine, causing blockage, rust, and definitely affecting the machine's operation. |

✅ The machine is a closed system. Prevents dust and other debris from entering the machine. Changing the water is easy.

✅ With a closed system operation, it prevents dust and sediment from entering the machine. Changing water is also convenient. |

| ❌ Cleaning made difficult.

❌ Cleaning the machine is difficult. |

✅ Cleaning made easy.

✅ Cleaning the machine is easy. |

| ❌ The machine is large, takes up quite a lot of work space.

❌ The machine is large and requires a lot of working space. |

✅ The machine is small, save working space.

✅ The machine is small in size, saving a lot of working space. |

| ❌ Short term

❌ Short lifespan |

✅ Long term

✅ Long service life |

| ❌ Cheap… but not worth it !

❌ Cheap but not worth the maintenance, repair and short lifespan, wasting budget in the future. |

✅ Expensive… but worth it

✅ More expensive but worth it, easy to maintain and helps reduce costs well. |

If interested or have questions, call LINE SCAN:

061-509-6388 (Chompoo)

098-997-4199 (Fern)

02-312-0227 (office)

E-mail : Sales@salecnc.com

Add Line: @123wotsb Fern (sales engineer) '

Add Line: @123wotsb Fern (sales engineer) '

Add Line: @sales Chompoo (sales engineer)

Add Line: @sales Chompoo (sales engineer)

Reviews

There are no reviews yet.