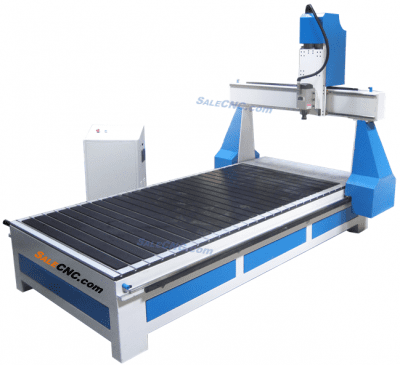

ขายเครื่องชิลเลอร์ รุ่น JL-6000 Chiller

Used for cooling CNC fiber laser machines. Easy to use, makes the CNC fiber laser machines not hot while working.

Chiller Chiller Water Cooling

ระบบทำความเย็น ระบบทำนำเย็น เครื่องทำความเย็น

เครื่องทำน้ำเย็นอุตสาหกรรม water chiller สำหรับโรงงาน

- Thailand is located in a tropical area. The weather is hot all year round. In the use of machinery, electronic equipment and other devices in industrial plants, when the temperature increases, the inside of the machine will overheat, resulting in equipment damage, inefficient operation and if the heat accumulates more and more, it may cause a fire. The heat in the machine is like the heat in a person's body. When our body temperature is higher than normal, we will get sick and will not be able to do things efficiently. Therefore, we take into account the maintenance of the machine and can solve the problem of high temperature machines by: Chiller Be a helper

- Chiller It is a cooling machine, a water chiller, both large and small. Its main function is to produce coolness, reduce the temperature and dissipate heat by using water as the main factor in exchanging and transferring coolness from the chiller. Currently, chillers are used in industrial plants to cool machines, maintain machines to last longer and help maintain the efficiency of the machines.

- Thailand is located in the tropical zone. It is hot all year round. In machine operation Electronic device and other industrial equipment when there is an increase in temperature causing the inside of the machine to overheat resulting in malfunctioning equipment not working efficiently and find more and more heat equations there may be a fire. Machine heat Is like the heat of a person's body, when the body temperature increases beyond normal we will get sick and unable to do things at their full potential Therefore, we consider the maintenance of the machine. And can solve problems with high temperature machines with Chiller to help.

- Chiller is a refrigeration. Water cooler There are both large and small. It is the main function of cold production reduce the temperature and cooling.

- Use water as the main medium for exchanging and dissipating heat from the cooling machine.

- Chillers are currently used in industrial plants to cool down machines, maintain them for a long time, and help maintain their efficiency.

- For example, closed-loop wells, hydraulic injection molding machines, and CNC machines.

- It uses water as the main body for exchanging and cooling from the chiller.

- Currently, chiller is used in industrial plants. For cooling of the machine Maintain the machine for a long time and help maintain the performance of the machine.

- For example : Closed system pond, Hydraulic injection molding machine and CNC Machine.

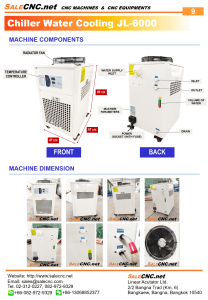

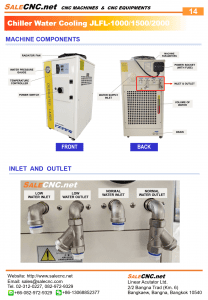

Machine Components

Use a lot for CNC Laser, CNC Fiber Laser, CNC CO2 Laser.

The normal state is 25-32 degree Celsius.

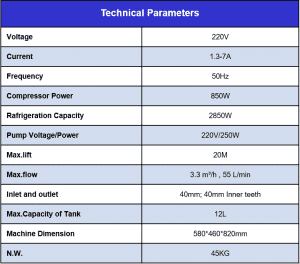

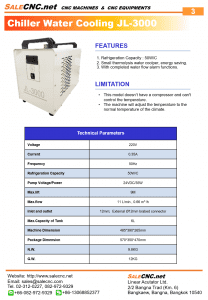

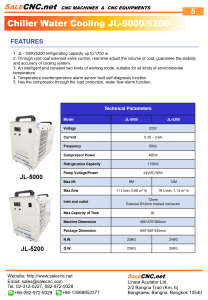

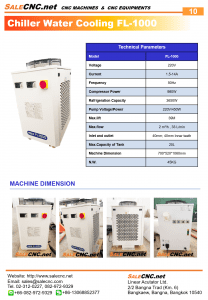

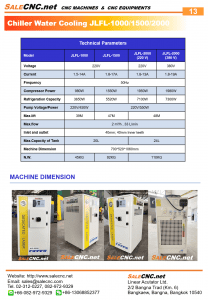

Technical Parameters

ลักษณะของเครื่อง

✔ Front

✔ ด้านข้าง

✔ Back

✔ Machine control panel

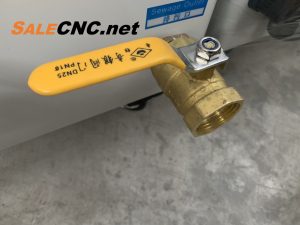

✔ inlet และ outlet

✔ รูปล่อยน้ำทิ้ง

Function เพิ่มเติม สามารถเลือกซื้อ inside diameter 19 หรือ 32 mm

ท่ออปล่อยน้ำทิ้ง inside diameter 32 mm

✔ Ventilation fan

Compare all models of water chillers

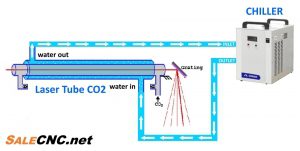

Working between CO2 Laser Tube and Chiller

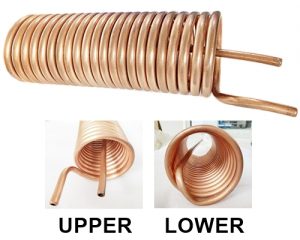

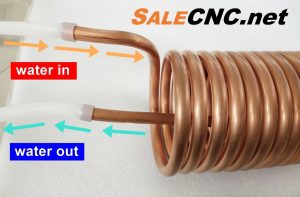

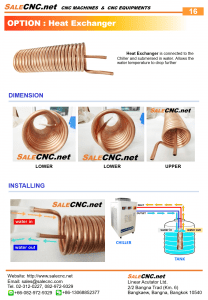

Additional options: Heat Exchanger

Heat Exchanger Connect to the Chiller and immerse in water to further reduce the water temperature.

The price is only 3,000 baht!!

Installation of Heat Exchanger with chiller

Heat Exchanger Accessories for chillers to further reduce water temperature | SALECNC.net

downloadUser Manual Chiller JL-6000 Click here

Features :

- Dual digital tube display, set the temperature and real-time temperature at a glance.

- Full power refrigeration, micro-cooling, heating control (plus configuration), suitable for various working conditions.

- Intelligent and constant working mode, suitable for various ambient temperatures.

- High precision temperature control, volatility can be controlled within 0.5 °C.

- With temperature overtemperature alarm, sensor fault self-diagnosis function.

- Have the compressor over the load protection, water flow alarm function.

- It has anti-freeze function and can better protect machine waterway components in the low temperature environment in the North.

feature :

- Digital display, can quickly set the temperature and real-time temperature.

- Full cooling, with heat control cooling, suitable for various working conditions.

- Intelligent and constant working mode suitable for different temperatures

- High precision temperature control, fluctuation can be controlled within 0.5 °C.

- If the temperature is abnormal, the sensor will self-diagnose the fault.

- More compressors than load, water flow alarm function

- It has anti-freeze function and can protect the components of the water machine in low temperature environment.

Maintenance matters :

- Weekly or HALF-MONTHLY cleaning of dust screen or filter dirt intake, in order to avoid causing high temperature alarm of water chillers and other malfunctions.

- Regularly disassemble the side panels of the machine and clean the dust and dirt attached to the condenser (radiator) with a high-pressure air gun.

- Replace the circulating water every two months and remove and clean the filters installed so as not to cause dirty water blockage and water flow alarm.

- Regular inspection of water joint pipe leakage, electrical wiring fixing screw loosening, to prevent poor circuit contact.

- Every 15-30 days, the filters need to be cleaned to clean and dust.

Maintenance :

- Clean the dust screen or dirt filter every 14 days to avoid high temperature of the cooling tank and other internal devices.

- Regularly remove the side panel of the machine and clean the dust and dirt stuck to the condenser (radiator) with a high-pressure air gun.

- Change the circulating water every 2 months. Change and clean the installed filter to prevent clogging of dirty water and prevent the tank flow warning signal.

- Regularly check the water pipe for leaks. Loosen the screws holding the wires to prevent bad contact with the circuit.

- Every 15-30 days, the filter must be removed for cleaning and dust removal.

Temperature controller :

|

Alarm display |

|

|

Fault code |

Fault name |

|

E01 |

Water temperature sensor failure |

|

E02 |

Over high water temperature |

| E03 |

Compressor pressure failure |

|

E04 |

Phase sequence error |

|

E05 |

The flow of water is not smooth |

|

E06 |

Water level alarm |

| E07 |

Compressor overload |

|

E08 |

Over low water temperature |

| E09 |

Room temperature sensor failure |

Temperature controller :

|

Warning signs |

|

|

Error code |

Error |

| E01 |

Water temperature sensor failure |

|

E02 |

The water temperature is too high. |

| E03 |

Compressor pressure failure |

|

E04 |

Phase sequence error |

| E05 |

The water flow is not smooth. |

|

E06 |

Water level alarm |

| E07 |

Compressor overload |

|

E08 |

Water temperature is lower than normal |

| E09 |

Room temperature sensor failure |

Matters needing attention :

- The equipment must be far away from fire source, heating body and electronic components with strong interference electromagnetic wave.

- Equipment is prohibited from carrying liquid transportation, so as not to damage internal components.

- The inlet and outlet of equipment should be more than 50cm away from obstacles, so as to avoid high temperature alarm failure.

- The equipment should not be inverted or inclined to more than 45 degrees, so as not to damage parts.

- The equipment must be placed horizontally, and the lock wheel must be well fixed.

- It is forbidden to start the machine without water, so as not to damage internal components.

- The length of the external waterway should not be too long, so as not to alarm the malfunction of the waterway, specifically refer to the pump head flow requirements.

Matters of interest :

- The device must be kept away from fire sources, heaters and electronic components that generate strong electromagnetic interference.

- Always drain water from the unit before transport to avoid damaging internal components.

- The inlet and outlet of the equipment should be more than 50cm away from obstacles to avoid failure of high temperature alarm.

- The machine should not be turned upside down or tilted more than 45 degrees to avoid damaging the parts.

- The equipment must be placed horizontally and the wheels must be locked to keep the machine in place.

- Do not turn on the device while there is no water to avoid damaging the internal components.

- The length of the external water passage should not be too long, so as not to cause abnormal water passage (refer to the pump head flow requirements).

Prompt Message :

- Capacity of water tank: 12L

- First adds water to it, then connects the water pipe, so as to remove the internal air and prevent the self-protection of the pump.

- The circulating water should be distilled water and purified water.

- When the water level is too low, the machine must be supplemented.

- Under extremely cold temperatures, a volume ratio of less than 20% ethanol or non corrosive antifreeze should be appropriately added.

- It is forbidden to add antifreeze fluid, water tank, and corrosive liquid to copper and stainless steel.

Notification message :

- Water tank capacity (Capacity of water tank): 12L

- First fill it with water and then connect the water pipe to remove the air inside and prevent the pump from protecting itself.

- Circulating water should be distilled water and purified water.

- When the water level is too low, add more water immediately.

- Under cold temperatures, the volume ratio of ethanol less than 20% or a suitable non-corrosive antifreeze should be added.

- Do not add antifreeze, water tank antifreeze, or corrosive liquids to copper and stainless steel.

How to set the Chiller temperature JL-6000 :

1.Before setting up, the machine is in the compressor state and the pump is running. (Is the set old temperature)

- Press the setting button > adjust the temperature as desired, with ↑ increases the temperature value and ↓ decreases the temperature value > setting button again.

- The temperature will gradually adjust down when the set temperature is reached. The machine will notify the status of the increase in the Bypass valve and Compressor stops working.

How to set the machine temperature Chiller JL-6000 :

- Before setting, the machine is in Compressor and Pump working state (the old set temperature).

- Give a button Set up > Adjust the temperature as desired by increasing the temperature and decreasing the temperature > Press the button. Set up Once again

- The temperature will gradually decrease. When the set temperature is reached, the machine will indicate the Bypass valve status and the Compressor will stop working.

ขั้นตอนการปรับอุณหภูมิเครื่องชิลเลอร์ Chiller ตั้งแต่รุ่น CW/JL5000 ขึ้นไป

Temperature adjustment procedure for Chiller model CW/JL6000

Chiller Water Cooling VS Cooling Tower

Cooling Tower Used in industry Hydraulic Injection Molding Machine Mostly because cooling towers have quite a few disadvantages. The machine is large, it is an open system that is difficult to maintain, dust and sediment are easily able to enter the machine, which negatively affects the operation and shortens the lifespan.

Therefore, the manufacturing industry tends to turn to use Chiller (Chiller Water Cooling) The machine is small, compact, saves working space, is a closed system, prevents dust and sediment well, and has a long service life.

| Cooling Tower | Chiller Water Cooling |

|---|---|

| ❌ Open system

❌ Open system operation |

✅ Closed system

✅ Closed-system operation |

| ❌ Since the machine is an open system Causing dust and other sediments to enter the machine easily. It will clog, rust and affect the usability of the machine.

❌ Since it works as an open system, dust, debris, etc. are very likely to enter the machine, causing blockage, rust, and definitely affecting the machine's operation. |

✅ The machine is a closed system. Prevents dust and other debris from entering the machine. Changing the water is easy.

✅ With a closed system operation, it prevents dust and sediment from entering the machine. Changing water is also convenient. |

| ❌ Cleaning made difficult.

❌ Cleaning the machine is difficult. |

✅ Cleaning made easy.

✅ Cleaning the machine is easy. |

| ❌ The machine is large, takes up quite a lot of work space.

❌ The machine is large and requires a lot of working space. |

✅ The machine is small, save working space.

✅ The machine is small in size, saving a lot of working space. |

| ❌ Short term

❌ Short lifespan |

✅ Long term

✅ Long service life |

| ❌ Cheap… but not worth it !

❌ Cheap but not worth the maintenance, repair and short lifespan, wasting budget in the future. |

✅ Expensive… but worth it

✅ More expensive but worth it, easy to maintain and helps reduce costs well. |

Interested or want to inquire? phone

082-972-9329 (Jimmy)

083-256-5981 (Komin)

02-312-0227 (office)

E-mail : Sales@salecnc.com

Reviews

There are no reviews yet.