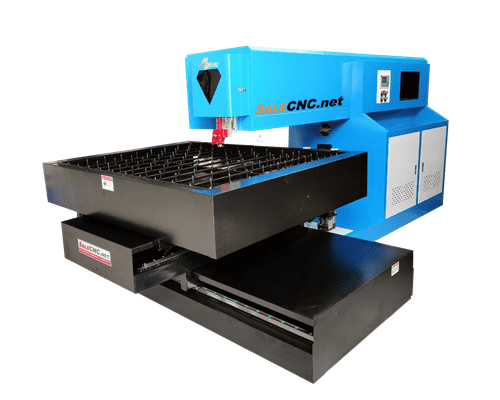

CNC Die Cut Laser Cutting Machine 450W 1512

Die cut

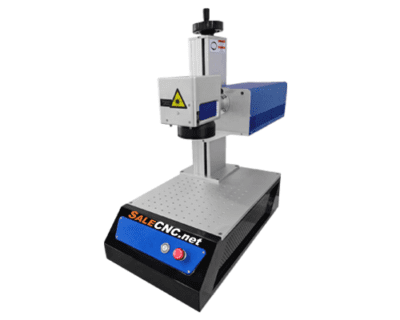

Focus Lens: 25mm-76.2

Focus Lens: 25mm-76.2

Reflection Lens 38mm

It is not possible to make a picture, it is written by a person.

Silicon is more reflective, while molybdenum is more durable.

laser cutting head

remote control

laser power supply

Diecut Wood finish product for die cut plastic or paper:

⚙️ How the process works

-

The construction:

-

The die is made by bending thin strips of hardened steel (knife) into the required shape and embedding them into a plywood or composite board.

-

-

Cutting process:

-

A sheet of plastic is placed under the die (or the die is pressed onto the plastic sheet).

-

A press (hydraulic or mechanical) pushes the die down onto the plastic with controlled force, slicing out the shape cleanly.

-

-

Result:

-

The cut-out matches the die shape exactly, enabling consistent mass production of identical pieces.

-

✅ Advantages of die cutting with knife die:

-

Cost-effective for large runs: Once the die is made, cutting is very fast and cheap.

-

Can cut many materials: Such as plastics, foam, rubber, thin metals, leather, paper.

-

Precision: Repeats exact shape every time.

⚙️ Work process

Mold structure:

This mold is made by bending a thin sheet of hardened steel (knife) into the desired shape and then embedding it into plywood or composite board.

Cutting steps:

A plastic sheet is placed under the mold (or the mold is pressed onto the plastic sheet).

A press (hydraulic or mechanical) presses the mold onto the plastic with controlled force, resulting in beautiful cut shapes.

result:

The cut parts match the shape of the mold, allowing for consistent production of large quantities of identical parts.

✅ Advantages of cutting the mold with a knife:

Cost-saving for mass production: Once the mold is made, cutting is very fast and cheap.

Can cut a variety of materials such as plastic, foam, rubber, thin metal, leather, paper.

Accuracy: Reproduce shapes accurately every time.

If interested or have questions, call

082-972-9329 (Jimmy)

083-256-5981 (Komin)

02-312-0227 (office)

E-mail : Sales@salecnc.com

Reviews

There are no reviews yet.