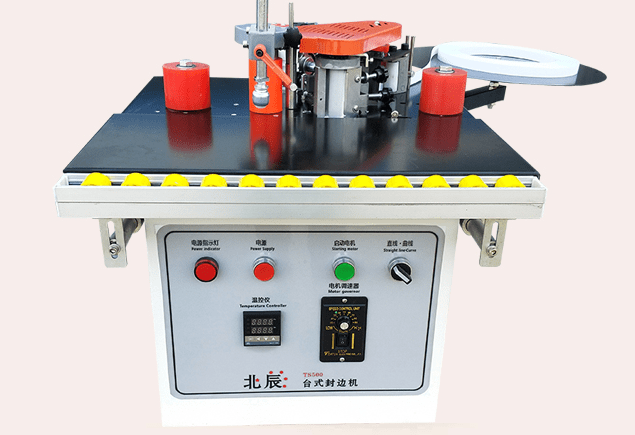

Edge banding machine (Wood Edge banding machine)

Edge banding machine is used for banding edges such as wooden boards, plywood, windows, edge trimming equipment. Edge banding using glue that can be applied on both sides. Then press with the machine to hide the corners to make it look smooth, shiny, and beautiful. It also has a polishing function to make it look smooth. The machine works efficiently and has a long service life. It is suitable for medium-sized furniture entrepreneurs and for use in general furniture factories.

วิดีโอการใช้งาน :

Heating Speed: 5-8min

Moving Speed: 0-6/min

Glue container: 1000ml

Edge Height: 7-60mm

Thinnest material can send: 0.3mm

Weight: 32kg

Size: 50x50x50cm

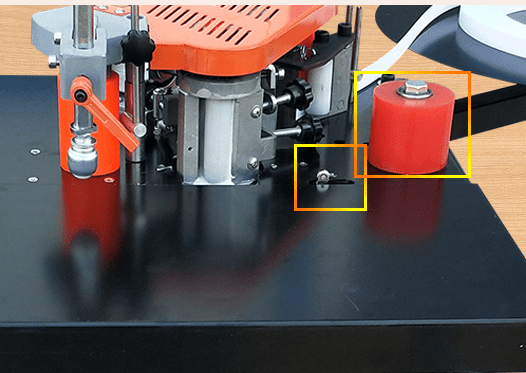

Millions of draws

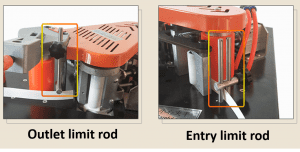

Outlet limit rod and Entry limit rod

Straight edge banding and Curve edge banding

Straight edge bands and curved edge bands

Straight edge banding :

- Press the switch to send he belt. Press the switch to send he belt.

- Leaving the switch break. Leaving the switch break.

Curve edge banding :

- Step-down foot switch to send belt. Step-down foot switch to send belt.

- Step on the foot switch again to break the belt.

Sample Edge Banding machine usage

Teach how to operate edge banding machine for wood, mdf, fixing edge.

Thai.

China

Free Gift:

Glue for edge 1kg (can stick up to 25-50m),

Extra Glue is only 180Baht/kg, Minimum order 50kg (50×180=9,000Baht)

Edge Cut manually+ End Cut manually

Side stick

Example of the machine's work

4

4

In general, using a wood edge bander is considered better than using a hand edge bander for several reasons:

- Accuracy and consistency:

Machinery: Edge banding machines provide precise and consistent application, ensuring consistent edges and a professional finish. This level of precision is difficult to achieve by hand.

Hands: Using hands can cause inconsistencies, inconsistent adhesion, and possible gaps or overlaps, especially on larger projects or when performed by less experienced individuals.

2. Speed and efficiency:

Machinery: Machinery can apply edge banding quickly and efficiently, greatly reducing the time required for large projects.

Hand: Hand work is labor intensive and time consuming, so it is not suitable for mass production.

3. Adhesion quality:

Machinery: The machinery uses special glue and precise heating to ensure a strong and durable bond between the edge band and the surface.

Hands: Achieving the same level of grip with hands is more challenging and can be unreliable, leading to flaking or peeling over time.

4. Agility and capabilities:

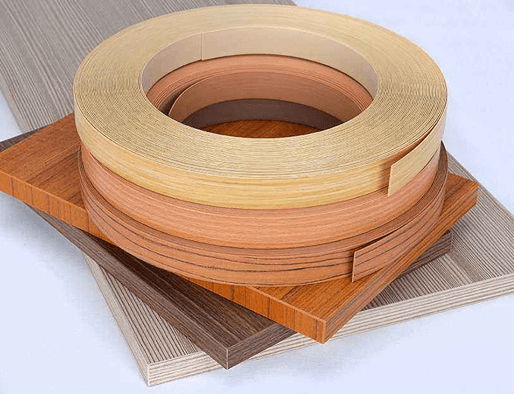

Machinery: Modern edge banding machines can accommodate different materials (PVC, ABS, wood veneer, etc.), thicknesses and edge profiles, making them more versatile.

Hand: Hand applications are more limited in terms of the types of edge banding that can be effectively applied and the complexity of the edge profile that can be managed.

5. Finished quality:

Machines: Machines generally produce cleaner, more professional results, including trimming and polishing that enhance the final look.

Hand: Achieving a similar finish by hand requires considerable skill and experience, and may not match the finish achieved by machine.

6. Reduce costs:

Machinery: Although the initial investment in edge banding machines may be high, they pay off in the long run with increased efficiency, reduced labor costs, and improved product quality.

Hand: Hand applications may have a lower upfront cost, but can become more expensive over time due to higher labor costs and potential quality issues leading to rework.

In summary, while hand-operated applications may be suitable for small, one-off projects or hobby projects, edge banders are a better option for professional woodworking, large-scale production, and consistent, high-quality results.

Using a wood edge banding machine is generally considered better than hand-applying edge banding for several reasons:

- Precision and Consistency:

- Machine: Edge banding machines provide precise and consistent application, ensuring uniform edges with a professional finish. This level of accuracy is challenging to achieve by hand.

- Hand: Hand application can lead to inconsistencies, uneven adhesion, and potential gaps or overlaps, especially over large projects or when performed by less experienced individuals.

- Speed and Efficiency:

- Machine: Machines can apply edge banding quickly and efficiently, significantly reducing the time required for large-scale projects.

- Hand: Hand application is labor-intensive and time-consuming, making it impractical for high-volume production.

- Quality of Adhesion:

- Machine: Machines use specialized adhesives and precise heat application to ensure strong, durable bonds between the edge banding and the substrate.

- Hand: Achieving the same level of adhesion by hand is more challenging and may not be as reliable, leading to potential peeling or detachment over time.

- Versatility and Capability:

- Machine: Modern edge banding machines can handle various materials (PVC, ABS, wood veneer, etc.), thicknesses, and edge profiles, offering greater versatility.

- Hand: Hand application is more limited in terms of the types of edge banding that can be effectively applied and the complexity of the edge profiles that can be managed.

- Finish Quality:

- Machine: Machines typically provide a cleaner, more professional finish, including trimming and buffing capabilities that enhance the final appearance.

- Hand: Achieving a similar quality of finish by hand requires significant skill and experience and may still not match the machine-applied finish.

- Cost-Effectiveness:

- Machine: While the initial investment in an edge banding machine can be high, it pays off in the long run through increased efficiency, reduced labor costs, and improved product quality.

- Hand: Hand application may have lower upfront costs but can be more expensive over time due to higher labor costs and potential quality issues leading to rework.

In summary, while hand application may be suitable for small, one-off projects or hobbyist work, a wood edge banding machine is the better choice for professional woodworking, large-scale production, and achieving consistent, high-quality results.

Reviews

There are no reviews yet.