Pipe bending machine, model TWG-50

| Model: TWG-50 | Detail Machines |

|---|---|

| Motor power | 3 KW. |

| Voltage | 380 VAC 50 Hz (3 Phase) |

| Size of bendable steel pipe | 16-51 mm.(0.5 – 2 inches) Steel pipes can be up to 3 mm thick. |

| Bendable angle angle | 5 – 180 degrees |

| Record the position of the adjustment | 9 positions |

| weight | 310 KG. |

| Device size | 930 x 680 x 850 mm |

| For more information, call 082-9729329 (Mee) | |

R x3 , Example OD35 35/2*3= R52.5mm

Comparison table of other models

| Model | TWG-25 | TWG-38 | TWG-50 | TWG-75 | TWG-75 Hi-Speed |

|---|---|---|---|---|---|

| Motor power | 2.2 Kw | 2.2 Kw (6 Pole Motor) | 3 Kw | 4 KW.(4 Pole Motor) | 4 KW.(4 Pole Motor) |

| Voltage | 380 VAC 50 Hz (3 Phase) | ||||

| Size of bendable steel pipe | 10-26 mm.(0.4 – 1.02 inches) Steel pipes can be up to 2 mm thick. |

16-38 mm.(0.5 – 1.5 inches) Steel pipes can be up to 3 mm thick. |

16-51 mm.(0.5 – 2 inches) Steel pipes can be up to 3 mm thick. |

76 mm.( 3 inches) Steel pipes can be as thick as 2-3 mm. |

76 mm.( 3 inches) Steel pipes can be as thick as 2-3 mm. |

| Curved corner | 5 – 180 degrees | ||||

| Record the position of the adjustment | 10 positions | 9 positions | |||

| weight | 180 KG. | 230 KG. | 310 KG. | 630 KG. | 630 KG. |

| Device size | 800 x 650 x 900 mm | 900 x 800 x 850 mm | 930 x 680 x 850 mm | 940 x 750 x 850 mm | 940 x 750 x 850 mm |

| Other | Hi-Speed : 3-5 rpm

(Motor spindle speed) |

||||

Download the manual for the Pipe Bending Machine model WG. Click here

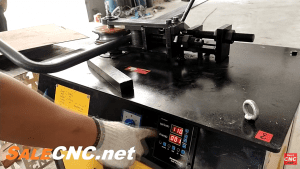

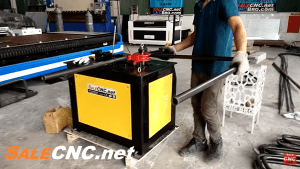

Machine display

Working example video

Main Performance And Characteristics (Overview)

Key Performance and Characteristics (Overview)

Pipe bending machineWG-38/-50/-75 CNC, this machine is mainly used to bend various steel pipes and stainless steel pipes of various materials with different pipe diameters.

WG-38/-50/-75 CNC pipe bender This machine is mainly used in bending various steel pipes and stainless steel pipes of various materials with different pipe diameters.

Compared with the existing pipe bending machine in the market, it has the advantages as below:

• Bending pipe is efficient.

• Gear transmission is durable and easy to maintain.

• Can bend thick tube and thin tube, cost-effective.

• Pedal + CNC operation, quick and worry-free

Compared with pipe benders available on the market, it has the following advantages:

• Efficient bending pipe

• The gears are durable and easy to maintain.

• Can bend thick and thin pipes cost-effectively.

• Step + CNC, fast and worry-free operation

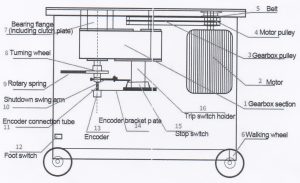

Machine Structure

Machine structure

- Gearbox

- Motor

- Gearbox pulley

- Motor pulley

- Belt

- Walking wheel

- Bearing flange (including clutch plath)

- Turning wheel

- Rotary spring

- Shutdown swing arm

- Encoder connection tube

- Foot switch

- Encoder

- Encoder bracket pate

- Stop switch

- Trip switch holder

Machine Installation And Debugging And Operation

Machine installation, debugging and operation

• Before the whole machine is installed, the following should be done:

1) Before installation and use, check that the whole machine parts and electrical appliances are complete and whether there are screws loose or damaged during transportation and handling;

2) The surface of the machine should be leveled to prevent vibration during operation and damage the components or electrical appliances.

• Before installing the entire machine, the following should be done:

1) Before installation and use, check whether all machine parts and electrical appliances are complete, whether there are loose screws or damage during transportation and handling.

2) The surface of the machine should be leveled to prevent vibration during operation and damage to components or electrical appliances.

• Turn on the power

1) After careful inspection, connect the power source to the power terminal.

2) Turn on the controller power switch.

Note: The machine should be placed on the ground smoothly. The power cable should be used within 50 meters with a minimum of 6 square millimeters of national standard copper cable and a leakage protection switch.

• Turn on the device.

1) After careful checking, connect the power supply to the terminals.

2) Turn on the power switch of the controller.

Note: The machine should be placed on a flat floor. The power cord should be within 50 meters with a national standard copper wire of at least 6 square millimeters and a leakage protection switch.

• No-load test machine

1) Turn on the power to turn on the controller power switch, you should see a normal digital display on the controller. If you do not see the normal digital display, please check if the power supply is out of phase and whether the voltage is normal or not, etc.

2) After correct operation, follow the “Operation Step 3 Angle Setting Operation” setting – an arbitrary angle (between 5 and 200°), step on the foot switch, check the motor's steering, such as reverse (the controller has no normal digital display) Please change the thread head; the motor rotates clockwise during operation and rotates counterclockwise when retracting.

• No-load tester

1) Turn on the power to switch on the controller power, you will see the normal digital display on the controller. If you can't see the normal digital display, please check if the power supply is out of phase and the voltage is normal, etc.

2) After the correct operation, follow the setting of “Step 3 Angle Setting” – arbitrary angle (between 5 and 200 °), step on the foot switch, check the motor steering, such as reversing (the controller does not have a normal digital display), the motor will rotate clockwise during operation, and rotate counterclockwise when reversing.

• Load test machine

1) Preparation before the test machine: Select and install the bending die (inner wheel, shape guide strip, etc.) according to the diameter and curvature of the curved steel pipe, and adjust the pinch device (internal pinch die) to the appropriate position.

2) Fixed length and tightened steel pipe: adjust the fixed length device according to the length of the steel pipe to be bent and clamp the steel pipe;

3) Angle setting: According to the “Control Panel Easy Description”, set the angle.

4) Bent steel pipe: foot pedal switch, one step at a time, each time bending one angle, then loosen the clamping device; repeat the “operation step 2) fixed length and tighten the steel pipe” bent steel pipe, take out after completion Steel Pipe.

5) Angle correction; When there is an error in one or several angles and the actual angle during the bending work, the angle correction can be performed according to the “simple description of the control panel”.

6) Repeat “Operation Step 2) Fixed Length and Tightening Steel Pipe and Operation Step 4) Bending Steel Pipe”, and re-run the machine so that mass production can be carried out.

• Load test machine

1) Preparation before testing machine: Select and install the bending die (inner wheel, shape guide bar, etc.) according to the diameter and curvature of the bent steel pipe, and adjust the squeezing device (inner pinch mold) to the appropriate position.

2) Fixed length and steel pipe tightening: Adjust the fixed length device according to the length of the steel pipe to be bent and tighten the steel pipe.

3) Angle setting: According to “Simple Description Control Panel”, set the angle.

4) Steel Pipe Bend: Step foot switch every time you bend one angle, then loosen the clamping device, repeat “Operation step 2)Fixed length and tighten steel pipe”, the steel pipe bend is taken out after completion of Steel Pipe.

5) Angle correction: When an error occurs in one or more angles and the actual angle during bending, angle correction can be performed according to the “Simple Description of the Control Panel”.

6) Repeat: “Operation step 2) Fixed length and tightening of steel pipe and operation step 4) Bending of steel pipe” and run the machine again to achieve mass production.

Safety of maintenance and maintenance equipment

Equipment Safety, Maintenance and Maintenance

1) Safety precautions for equipment

A. Be sure to read this manual carefully before installing and using the equipment. In order to ensure the personal safety of the operator and the normal use of the equipment, the precautions and operating instructions of this manual must be strictly observed.

B. During the use of the machine, do not move or modify the various switches and other safety devices of the equipment; do not come close to the motor and the running part, do not touch the steel pipe being processed; do not install install other objects on the equipment without permission.

C. All power supply must be cut off for maintenance of the machine, and it must not be operated with electricity to avoid danger.

1) Safety precautions for equipment

A. Please read this manual carefully before installing and using the equipment. For the personal safety of operators and normal use of the equipment, the precautions and operating instructions in this manual must be strictly followed.

B. During use, do not move or modify the switches and other safety devices of the equipment. Do not approach the motor and working parts, do not touch the steel pipe under operation. Do not install other objects on the equipment without permission.

C. All power supply must be cut off for machine maintenance and no electricity must be used to avoid danger.

2) Maintenance and maintenance of equipment

A. Read the manual carefully before maintenance. Follow the operation steps strictly. When the equipment is used outdoors, it should be protected from rain, sun, sand, dust, etc. into the electrical control system; the equipment must be cut before maintenance. Turn on the main power.

B. It is forbidden to disconnect the power switch without authorization when the device is running, which will easily damage the device.

C. When the equipment is not used for a long time: Disconnect the main power supply, make the parts of the equipment in non-working state, cover the equipment with machine cloth, and apply anti-rust oil to the place where the equipment is easy to rust.

D. Regular routine maintenance matters

o When the end of each shift is completed or started, clean the equipment to eliminate iron oxide and debris.

o Monthly routine maintenance: Check the mechanical parts for oil leakage and looseness, if any, should be disposed of immediately. Look for butter inside the gearbox.

o Weekly routine maintenance: Whether the control device is hygienic, check whether the connection line is loose, and clean the dust of each control component.

2) Maintenance and servicing of equipment

A. Read the manual carefully before maintenance. Strictly follow the operation steps. When using the equipment outdoors, it should be protected from rain, sunlight, sand, dust, etc. In the electrical control system, the equipment must be cut off before maintenance. Turn on the main power switch.

B. Do not disconnect the power switch without permission when the equipment is working, which will easily damage the equipment.

C. When the equipment is not in use for a long time: Disconnect the main power supply, make the parts of the equipment in a non-working state, cover the equipment with a cloth, and apply anti-rust oil in the areas where the equipment is easy to rust.

D. Routine maintenance is normal.

o At the end of each shift or start-up, clean the equipment to remove iron oxide and debris.

o Monthly maintenance: Check the mechanical parts for oil leaks and looseness, if any, remove them immediately. Look for butter in the jar.

o Weekly maintenance: Is the controller sanitary? Check if the connection cables are loose and clean the dust of each control component.

How to use Pipe Bending Machine WG-38/-50/-75 CNC round and square bending | SALECNC.net

0:15 Demonstration of bending round steel pipes

0:50 Bend the pipe 90 degrees.

1:39 Characteristics of the bent pipe

1:50 Teach how to set up and use the machine.

Change mold (mold) Bending ball, round mold - square mold, steel pipe bending machine Pipe Bending Machine | SALECNC.net

Sample work pieces

Bending the structural steel pipes of the roof using a pipe bending machine.

Reviews

There are no reviews yet.