Linear Rail model HGR Slide rails, sliding rails

HGR30 – 2 meter

- Slide rails are machine tools that are long rails.

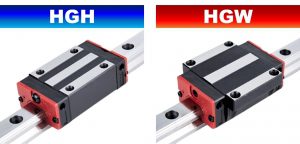

- There is a square block on top that acts as a weight-bearing device, whether it is HGH, HGW, or SBR.

- Slide rails come in various sizes and lengths to suit the job.

- Strong, durable and easy to install.

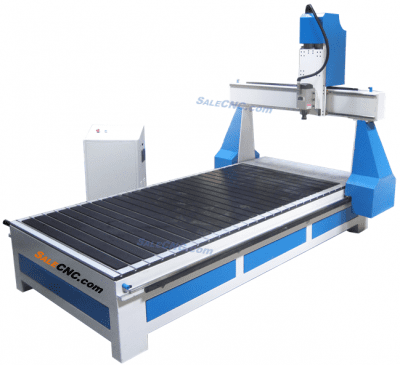

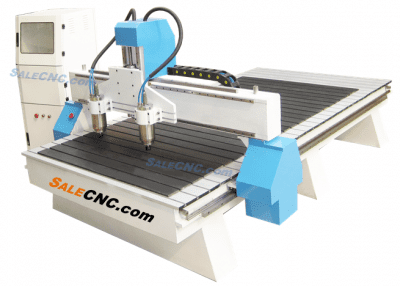

- The slide rail can also be applied to a wide range of applications, such as photocopiers, CNC machines, automotive industry, textile industry, etc.

Specification : Limited information / Specifications of the slide rail (Linear Rail HG)

| Model Size (mm) | HG15 | HG20 | HG25 | HG30 | HG35 | HG45 |

|---|---|---|---|---|---|---|

| Rail Length (mm) | 62 | 78 | 84 | 98 | 113 | 140 |

| Distance from the Edge to the Center of the First Hole (from Left) | 20 | 20 | 20 | 20 | 20 | 22.5 |

| Distance from the Edge | Tolerance of E value for standard rail is ± 0.5mm. | |||||

Dimensions

| Model Size (mm) | HG15 | HG20 | HG25 | HG30 | HG35 | HG45 |

|---|---|---|---|---|---|---|

| No. of Holes | 1 | 2 | 2 | 2 | 2 | 2 |

| Head Bolt Hole Diameter (mm) | 7.5 | 9.5 | 11 | 14 | 14 | 20 |

| Bolt Hole Spacing – Length (mm) | 60 | 60 | 60 | 80 | 80 | 105 |

Features : Features of the slide rail (Linear Rail HG)

1. Easy lubrication

With a traditional sliding system, insufficient lubrication causes wear on the contact surfaces. Also, it can be quite difficult to supply sufficient lubrication to the contact surfaces because finding an appropriate lubrication point is not very easy. With a linear motion guideway, grease can be easily supplied through the grease nipple on the linear guideway block. It is also possible to utilize a centralized oil lubrication system by piping the lubrication oil to the piping joint.

1. Easy lubrication

With conventional sliding systems, insufficient lubrication will cause wear on the contact surfaces. It can also be difficult to supply sufficient lubrication to the contact surfaces, as finding the right lubrication point is not easy. With Linear Rails, grease can be easily supplied through the grease nipple on the Sliding Block. A centralized oil lubrication system can also be used by delivering the lubrication oil to the pipe joints.

2. Easy installation

Installing a linear guideway is fairly easy. Grinding or milling the machine surface, following the recommended installation procedure, and tightening the bolts to their specified torque can achieve highly accurate linear motion.

2. Easy to install

Installation of Linear Rail is relatively simple. Grinding or milling the machine surface according to the recommended installation steps and tightening the bolts to the specified torque will achieve highly accurate linear movement.

1. Place the slider parallel to the guide rail.

2. Gently push the slider into the guide rail.

3. The slider slides into the guide rail.

4. The installation is over, without dropping the steel ball.

When installing, do not take out the plastic false rails in the slider in advance, otherwise the steel balls in the slider will easily fall out during assembly and it will not be able to be installed and used normally! When disassembling, the false rail cooperates with the disassembly to prevent the beads from falling off.

When installing, do not remove the plastic false rail in the slider in advance, otherwise the steel ball in the slider will easily fall out during assembly, and it will not be able to be installed and used normally! When disassembling, the false rail works together with the disassembly to prevent the bead from falling out.

3. High speed motions is possible with a low driving force.

Because linear guideways have little friction resistance, only a small driving force is needed to move a load. This results in greater power savings, especially in the moving parts of a system. This is especially true for the reciprocating parts.

3. High speed movement is achieved by using low driving force.

Since the guide rail has little frictional resistance, only a small amount of driving force is required to move the load, resulting in greater energy savings, especially in the moving parts of the system, especially the piston parts.

4. Long life with high motion accuracy

With a traditional slide, errors in accuracy are caused by the counter flow of the oil film. Insufficient lubrication causes wear between the contact surfaces, which become increasingly inaccurate. In contrast, rolling contact has little wear; therefore, machines can achieve a long life with highly accurate motion.

4. Long service life with high movement accuracy.

With traditional slides, the accuracy error is caused by the backflow of the oil film. Insufficient lubrication causes wear between the contact surfaces, which becomes more and more inaccurate. In contrast, the rolling contact has less wear, so the machine has a long service life with high precision movement.

5. High positional accuracy

When a load is driven by a linear motion guideway, the frictional contact between the load and the bed desk is rolling contact. The coefficient of friction is only 1/50 of traditional contact, and the difference between the dynamic and the static coefficient of friction is small. Therefore, there would be no slippage while the load is moving.

5. High position accuracy

When the load is driven in the linear motion direction, the friction contact between the load and the worktable will roll back and forth. The friction coefficient is only 1/50 of the conventional contact, and the difference between the dynamic and static friction coefficients is small, so there will be no slipping while the load is moving.

6. Equal loading capacity in all directions

With this special design, these linear guideways can take loads in either the vertical or horizontal directions. Conventional linear slides can only take small loads in the direction parallel to the contact surface. They are also more likely to become inaccurate when they are subjected to the loads.

6. Equal loading capacity in all directions.

By designing these guide rails, they can be loaded either vertically or horizontally. Conventional Linear Rails can only carry a small amount of load in the direction parallel to the contact surface. They also tend to be more inaccurate when subjected to a load.

If interested or have questions, call

061-509-6388 (Chompoo)

098-997-4199 (Fern)

02-312-0227 (office)

E-mail : Sales@salecnc.com

LINE SCAN:

Add Line: @123wotsb Fern (sales engineer) '

Add Line: @123wotsb Fern (sales engineer) '

Add Line: @sales Chompoo (sales engineer)

Add Line: @sales Chompoo (sales engineer)

Reviews

There are no reviews yet.