Cake packing machine

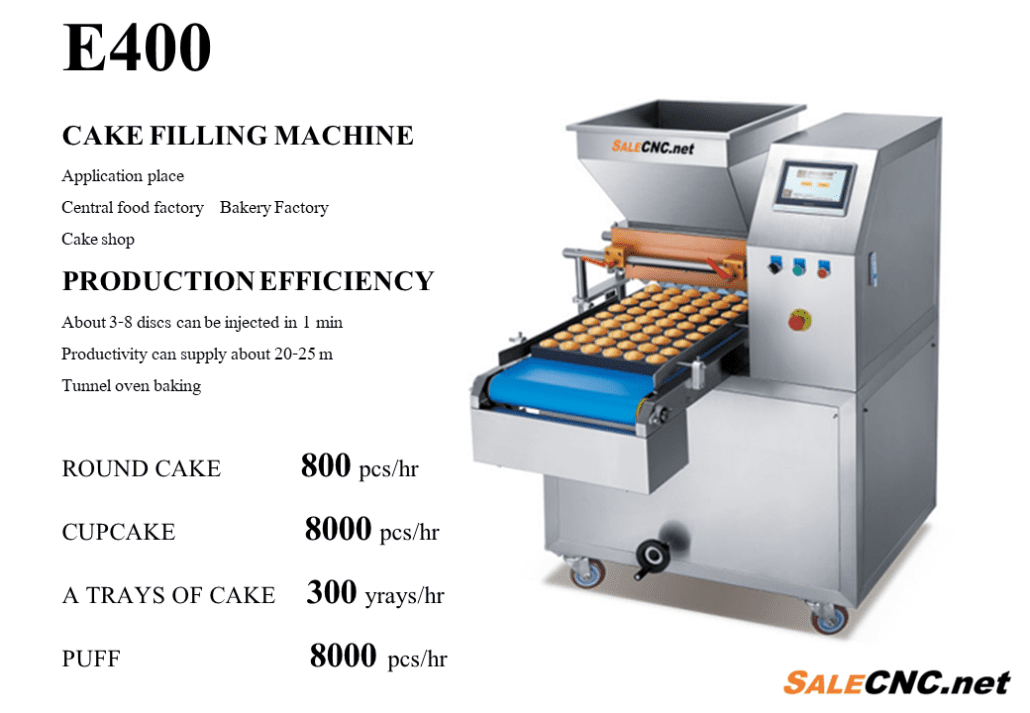

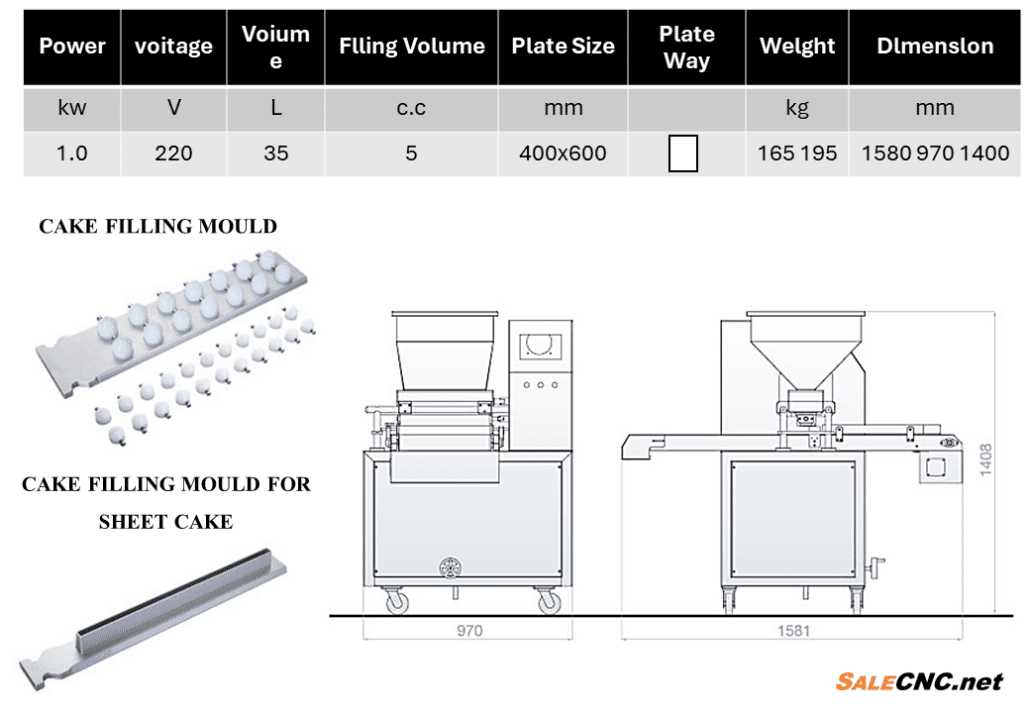

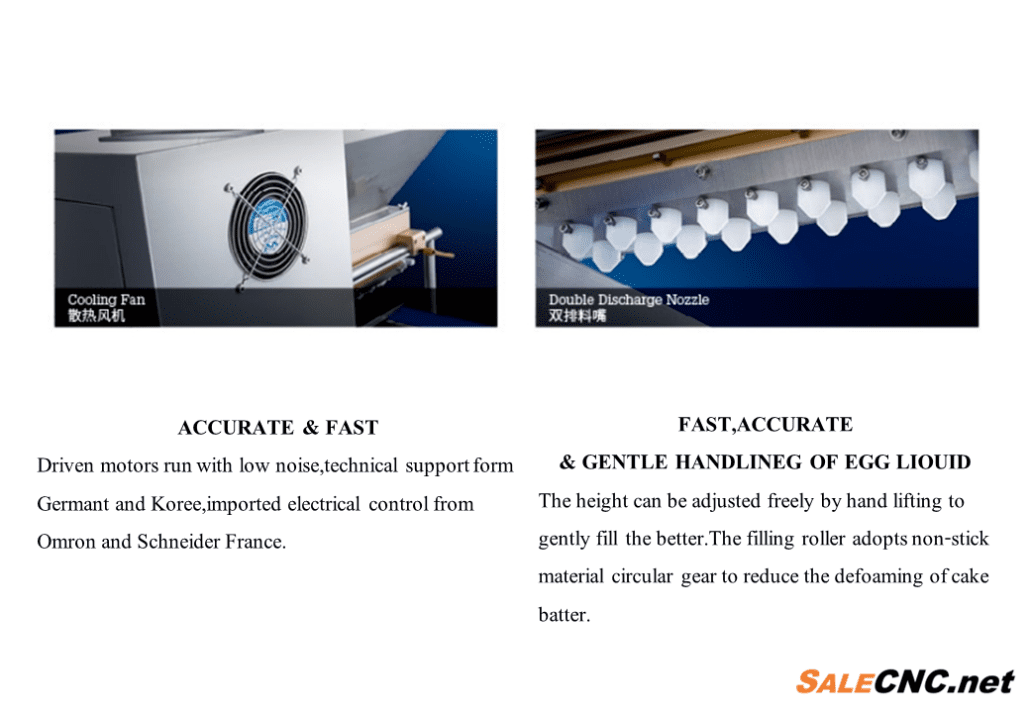

cake filling machine

Ultrasonic cutting machine is a special device that uses ultrasonic vibrations to cut through materials such as food, textiles, plastics, and more. Here’s how it works:

Working principle: Ultrasonic cutting machine vibrates the blade at a frequency of 20,000 to 40,000 times per second (20 – 40 kHz). This high frequency vibration allows for precise and efficient cutting.

Applications: Ultrasonic cutting machines find use in industries where accuracy and cleanliness are important. For example, in the food industry, ultrasonic cutting prevents sticking and breakage, allowing precise cutting without compromising product integrity.

strength:

Ensures high precision in cutting both simple and complex shapes.

Reduces dust and prevents edge fraying

Save time and money by eliminating the need for additional processing steps.

An ultrasonic cutting machine is a specialized device that utilizes ultrasonic vibrations to cut through various materials such as food, textiles, plastics, and more. Here's how it works:

- Principle of Operation: The ultrasonic cutter vibrates its blade at a frequency of 20,000 to 40,000 times per second (20 – 40 kHz) . This high-frequency vibration allows for precise and efficient cutting.

- Application: Ultrasonic cutting machines find applications in industries where accuracy and cleanliness are crucial. For example, in the food industry, ultrasonic cutting prevents sticking and crumbling, resulting in precise cuts without compromising product integrity.

- Advantages:

- Ensures high accuracy in cutting both simple and complex shapes .

- Minimizes dust and prevents fraying of edges .

- Saves time and money by eliminating the need for additional processing steps.

082-972-9329 (Jimmy)

083-256-5981 (Komin)

02-312-0227 (office)

E-mail : Sales@salecnc.com

Reviews

There are no reviews yet.