Steamed Bun Maker, Automatic Steamed Bun Filling Machine

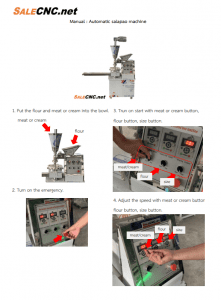

Automatic Bun Salapao Machine

Automatic filling and bun making machine It is a machine for producing various types of steamed buns, both round without pleats or with 12 pleats. The machine is widely used in various factories, cafeterias, baking schools, bakeries, and dessert shops. This steamed bun making machine can produce a large quantity in a short time and at high speed. It helps you save time and control production costs, including labor, ingredients, and raw materials, plus it also has a standard size.

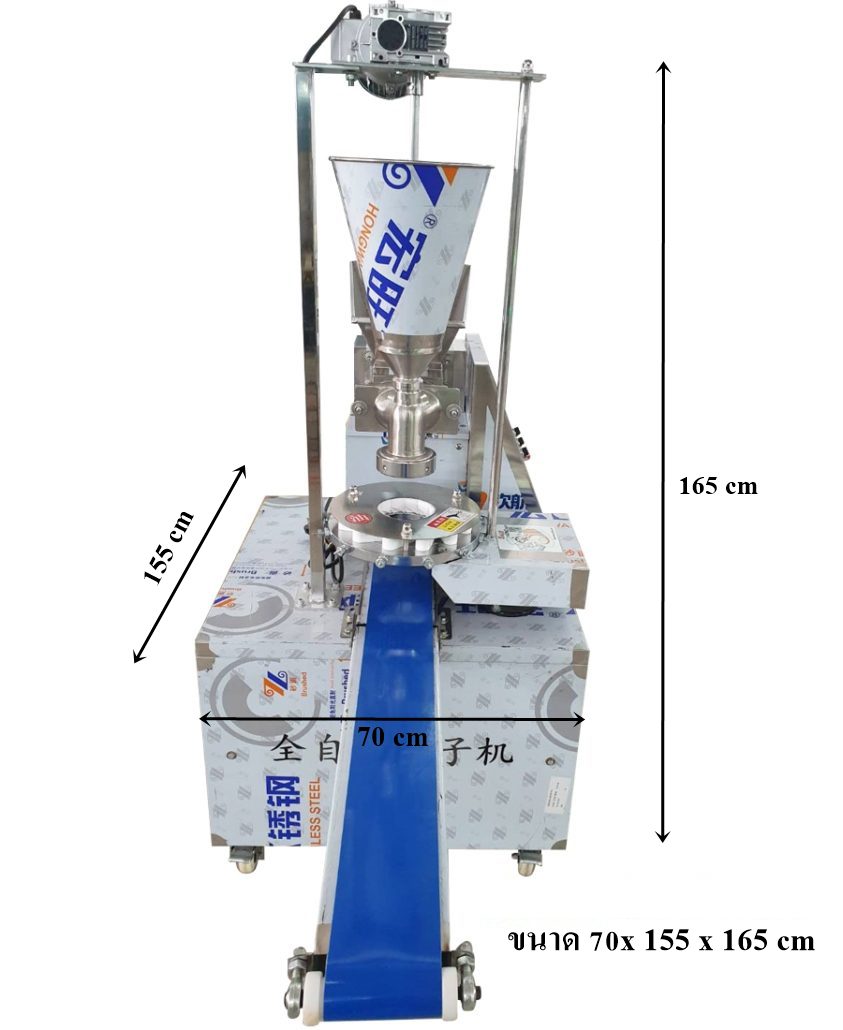

Placement area 70 x 155 x 165 cm

Machine weight 134.5 KG.

Video of how the bun making machine works

Salapao Machine, Automatic Bun Making Machine, Automatic Bun Making Machine, Salapao Machine

Automatic Salapao Machine, Colored Salapao Machine, Fantasy, Automatically shape and put in the filling of the buns.

Mini buns, mini buns, small buns, can be produced quickly, beautifully wrapped, easy to sell, good profit.

Make round buns with sweet filling using the Automatic Salapao Machine.

- Salapao Machine, Automatic Chinese Bread Machine Maker, Bun Maker, Made of Stainless Steel

- You can be sure that there are no toxic residues from the production machine.

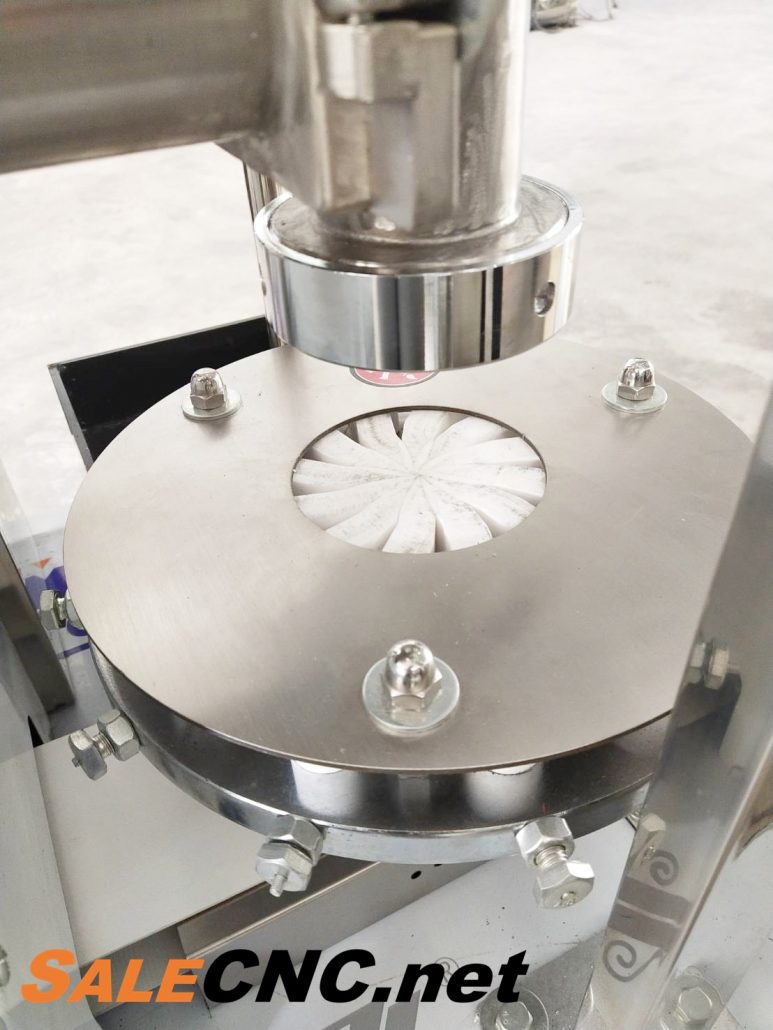

- Can be produced with 12 pleats or without pleats.

- You can customize the size of the buns and add the filling.

- 3 seconds produces 1 large ball.

- Reduce the time to make buns, reduce costs, and standardize the size of the buns.

Can be made from 25 - 200 grams.

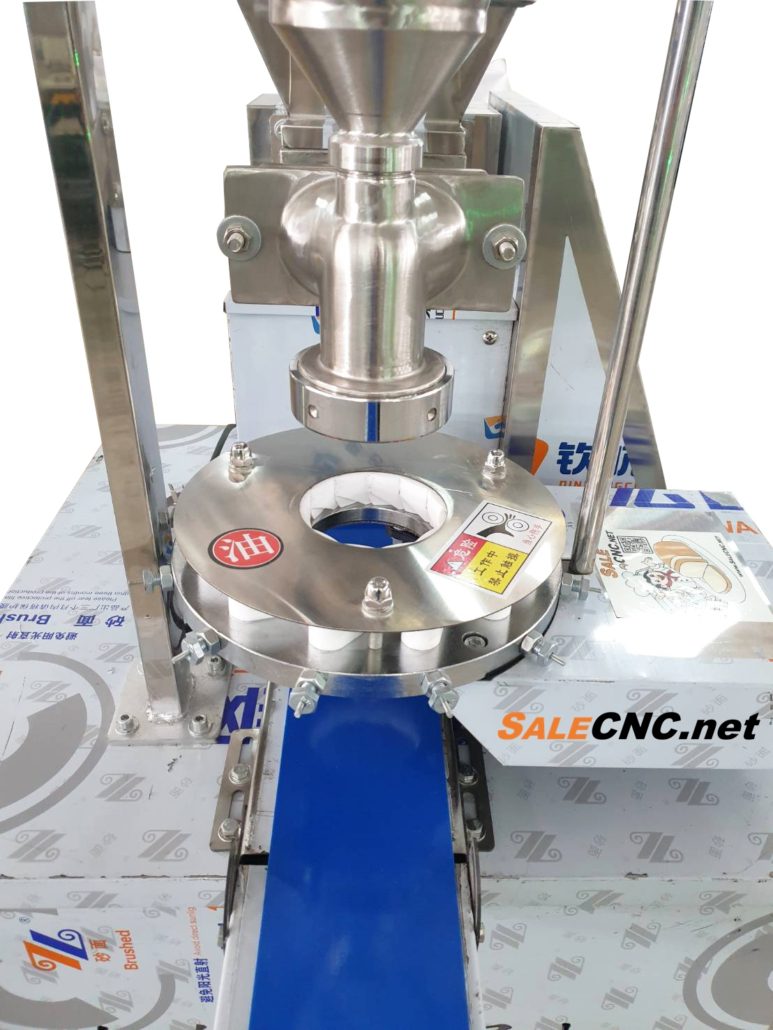

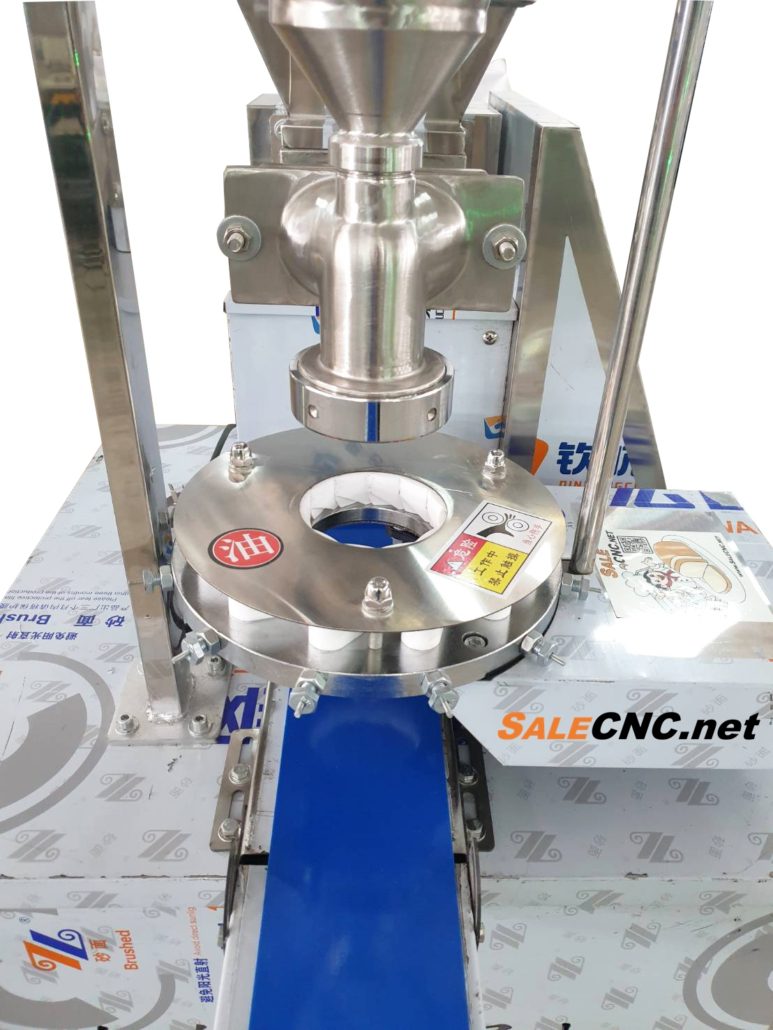

Front view of the device (taken from the actual device)

The side area has more space and is wider.

The front of the machine is strong and durable.

2 in 1 can do both types, round type and pleated type.

Front view

Side view

Back view

Performance and features

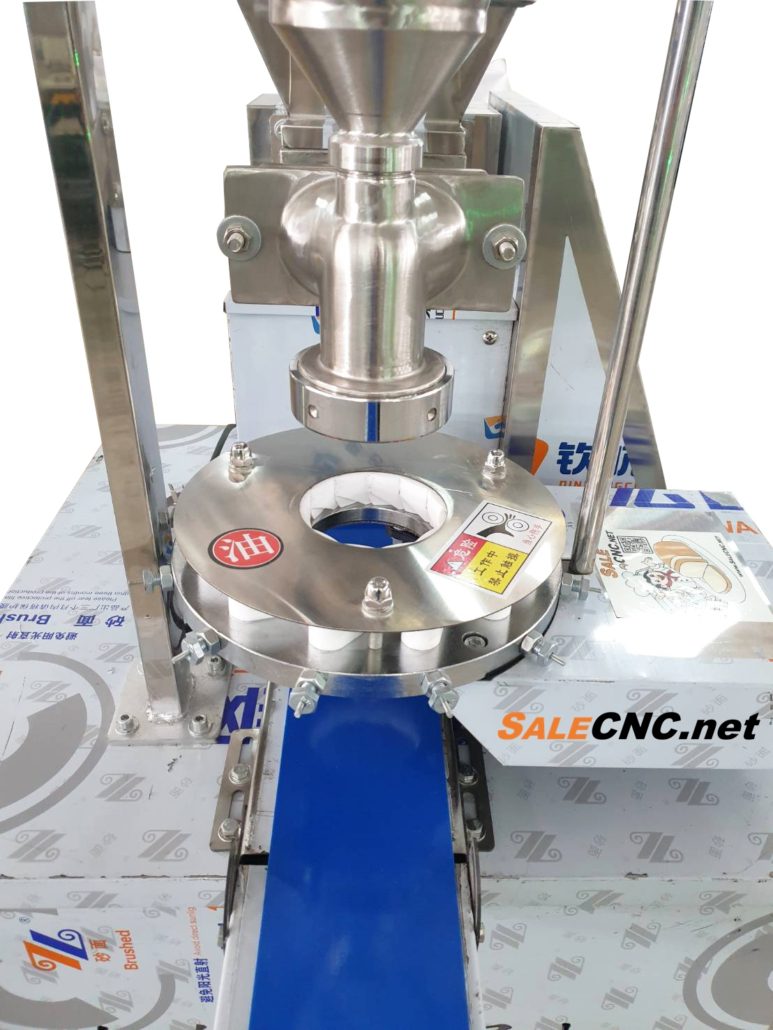

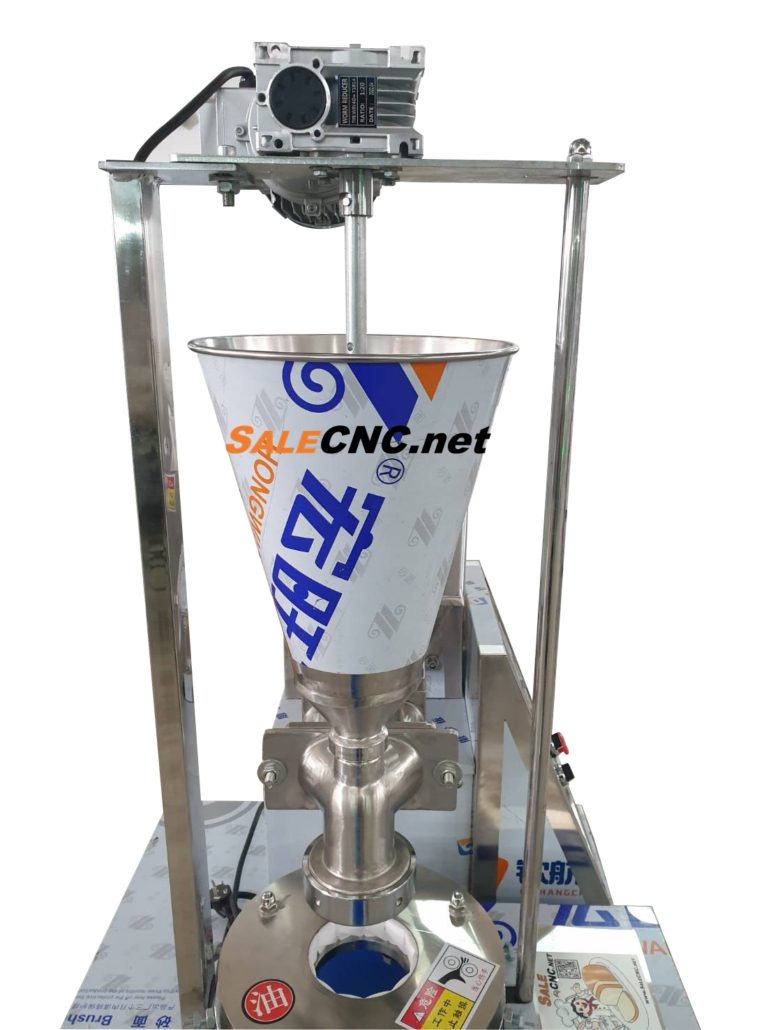

- This automatic stuffed bun making machine uses spiral kneading, then vertically compresses into a cone shape, pushes with a screw driving surface, and has a suction pump to help put the filling in the center of the dough.

- The raw materials are kneaded and shaped, all parts of the machine can be controlled, the frequency can be adjusted, the size of the buns can be adjusted, and the filling can be controlled.

- The machine structure design is compact, food parts and machine shell can be disassembled and easy to maintain.

- The steamed bun machine is made of Stainless 304 stainless steel, which is a good grade of metal, suitable for food processing machinery. Food Grade meets the standards of national food hygiene requirements. It has a beautiful appearance and is safe for users.

The buns are pleated or plain.

Technical parameters

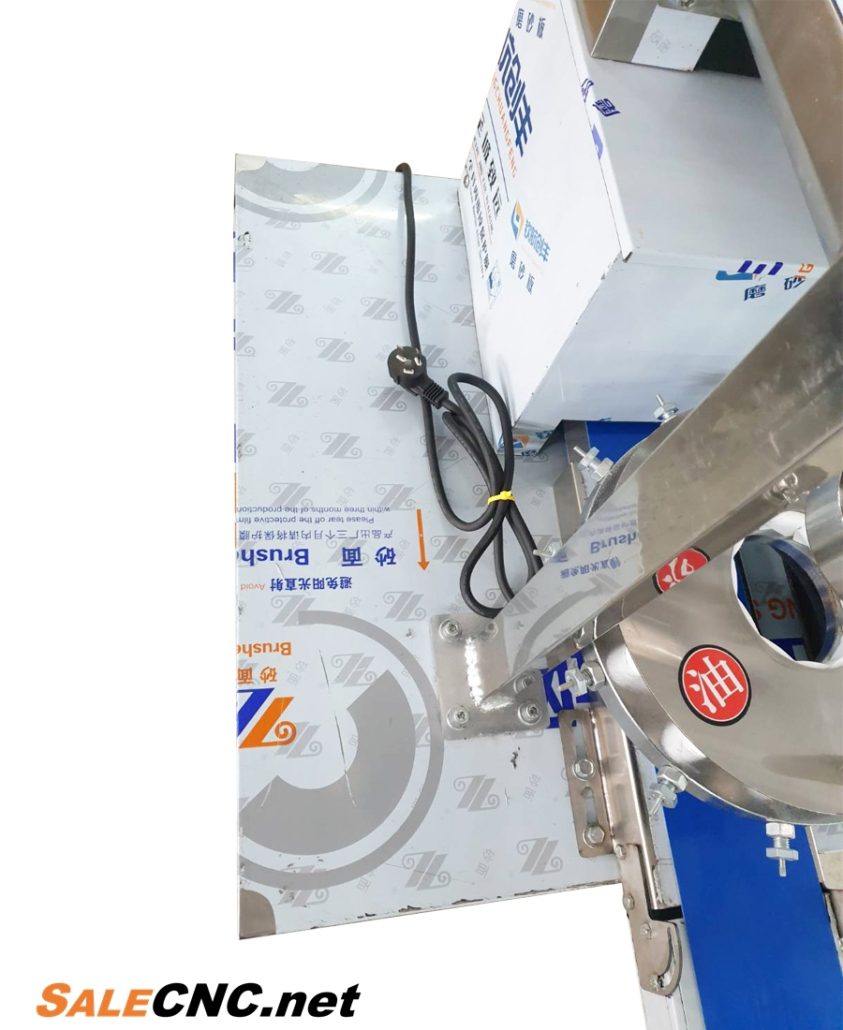

Conveyor belt for removing buns from the machine

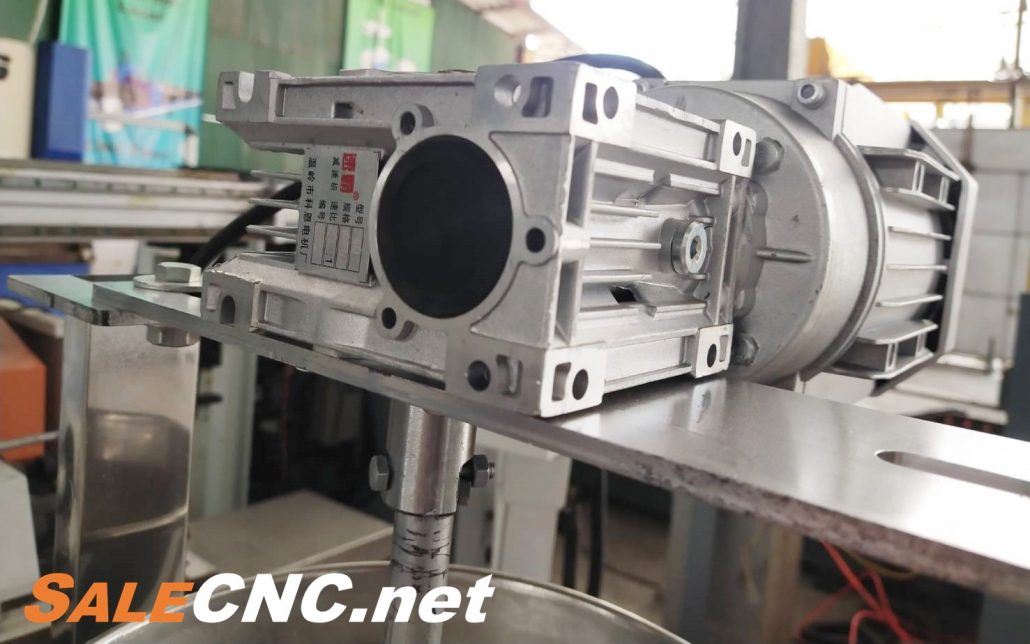

The motor on top helps push the filling into the center of the dough.

Controller page controls all parts of the machine.

Real machine video

Working principle

- It starts with a spiral kneading and rolling machine that is uniformly pressed vertically and squeezed into a hollow tube.

- The filling system is cut and mixed without using anti-viscosity water with filling. The powder is injected into the hollow tube at the appropriate speed through the filling tank, feeding tube and outlet mouth.

- When reaching the cylindrical forming point, the system will form it into a noodle spout and cut the dough into 1 bun in a round shape or with 12 pleats.

- Once the shape is complete, the buns are automatically dropped onto the conveyor belt.

✅ Make 12 pleated buns.

✅ Make buns that are smooth and have no pleats.

✅ The buns will start to grow in size at a temperature of 35 – 45 degrees Celsius.

Techniques

If top is thick the bottom is thin, then use mold bigger. Small mold, big bun = bottom thin

If top is thin the bottom is thick, then use mold smaller Big mold, small bun = bottom thick

If the top is thick and the bottom is thin, use a larger mold. Small mold, big buns = thin bottom.

If the top is thin and the bottom is thick, use a small mold, a large mold, small buns = thick bottom.

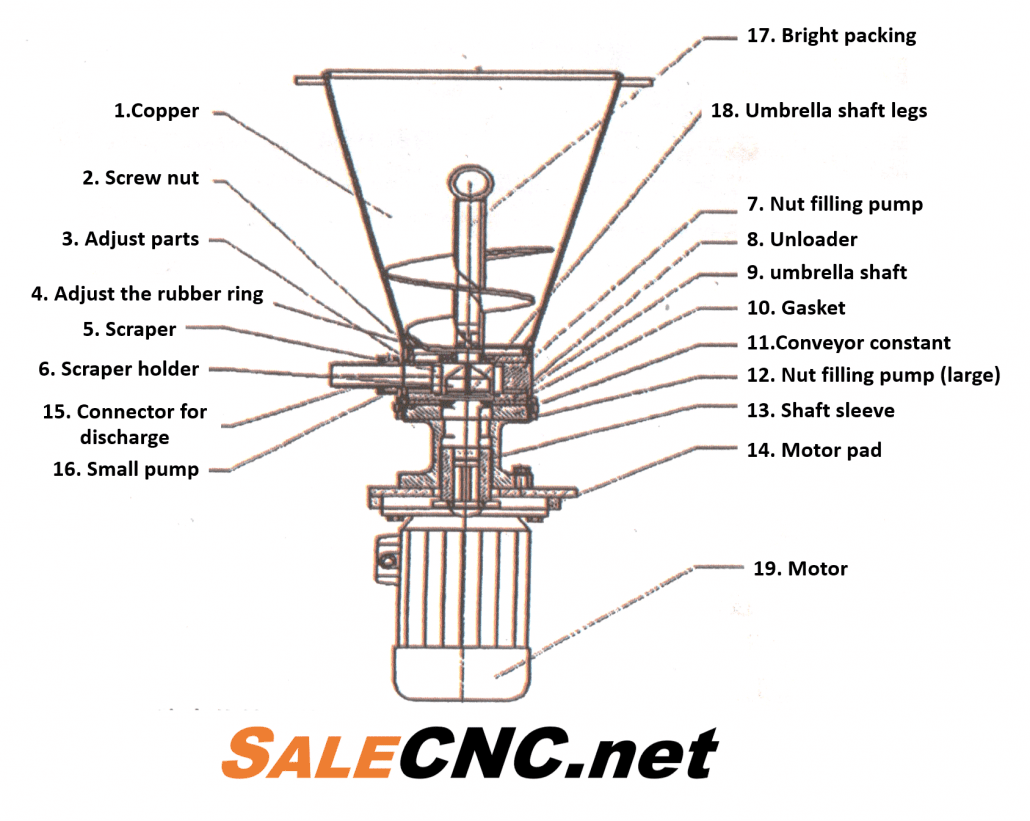

component

- Container

- Threaded nut

- Adjust parts

- Adjust the rubber ring

- razor

- Razor Holder

- Filling pump nut

- Unloader

- Umbrella shaft

- Gasket

- Fixed conveyor belt

- Filling pump nut (large)

- Shaft sleeve

- Motor pad

- Discharge connector

- Small pump

- Bright packed

- Umbrella shaft legs

- Motor

Safety precautions

1. Make sure that the grounding wire is connected before turning on the power.

2. Please make sure that the ambient temperature of the machine is between 5 degrees and 35 degrees. It is recommended to install an air conditioner to keep the machine in the best working temperature.

3. Do not wear slippers or go barefoot while using the machine.

4. Close the sealing plate of the forming plate and tighten the screws before starting the machine.

5. The machine must not operate in reverse direction, otherwise the internal components will be damaged.

6. During operation, there must be a caretaker (at least 1 person) and it is strictly forbidden to reach into the dough kneading screw and filling chamber to avoid accidents.

7. Do not put your hand or hard objects into the molding block when starting to avoid accidents and damage to the molding block.

Practices

- Users must pay attention to removing and installing accessories on the machine. During the installation process, they must be firmly fastened and locked. Check every time before turning on the machine.

- Automatic bun pump must be equipped with a ground wire.

- Electric current cannot be used in the reverse direction, otherwise the machine parts will be damaged.

- Do not insert your hands into the operating parts.

- Avoid placing equipment or tools, or other solid objects on the machine during operation.

Home electrical appliances AC220 V

Cleaning and maintenance

- After using the bun maker, it must be disassembled, cleaned, and then reassembled.

- Special molded knife molds should be disassembled for cleaning and smearing with cooking oil for future use. At the same time, to extend the life of the mold

- For long-term use parts, grease should be applied to lubricate the cam grooves of the forming plate.

Dough compartment for making steamed buns

Bun filling compartment

All parts can be disassembled for cleaning.

Troubleshooting

| problem | cause | How to fix |

|---|---|---|

| Thin-bottomed steamed buns with leaky filling | The buns are thick and short, resulting in insufficient space for filling. | Change the thickness of the bun skin or make the bun taller to allow enough space for the filling. |

| The buns are too thin and the filling is leaking out. | Quickly shaping the buns while kneading the dough causes the filling to leak out. | Tighten the spring and rollers that are tightened around the forming plate. |

| The bun is hollow or the bun filling is not evenly distributed. | The filling of the bun is too hard and cannot flow smoothly into the tube. | Adjust the recipe for the bun filling to be softer, thinner, and smoother than before. The ingredients must be consistent. |

Add Line: @123wotsb Fern (sales engineer)

Add Line: @123wotsb Fern (sales engineer)  Add Line: @sales Chompoo (sales engineer)

Add Line: @sales Chompoo (sales engineer)

Reviews

There are no reviews yet.